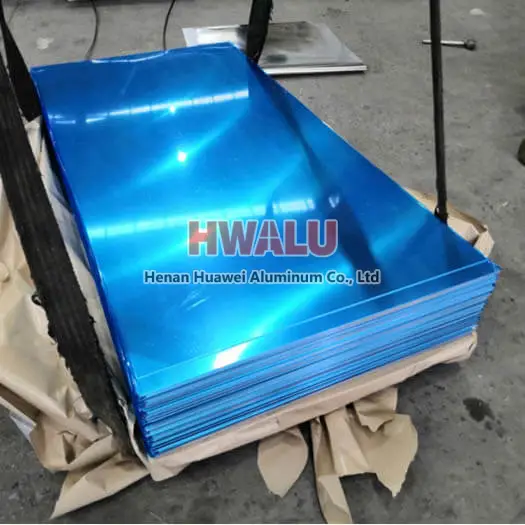

Introduction At Huawei Aluminum, we specialize in the production and wholesale of high-quality 3mm aluminum sheets. Our products are renowned for their durability, corrosion resistance, and versatility in various industries. With a wide range of alloy models and specifications, our aluminum sheets cater to diverse applications from construction to aerospace. Key Features Durability: Our 3mm aluminum sh ...

Price list of aluminum plates for door Date:Based on January 5th,2022 SMM Price 2570.39USD Date LME LME Weekly Price 2022-12 LME Average 2022-12 SMM Average 2022-12-26(Monday) / 2358.33$ 2394.88$ 2721.60$ 2022-12-27(Tuesday) / 2022-12-28(Wednesday) 2343$ 2022-12-29(Thursday) 2371.5$ 2022-12-30(Friday) 2360.5$ Notes 1. Prices are updated at 10:00 am on weekd ...

There are fewer manufacturers producing 2000 series aluminum sheets in China. The quality is not yet comparable to that of foreign countries. At present, the imported aluminum plates are mainly provided by Korean and German producers. With the development of China's aerospace industry, 2000 series aluminum plate production technology will be further improved. 2000 series aluminum plate is characterized ...

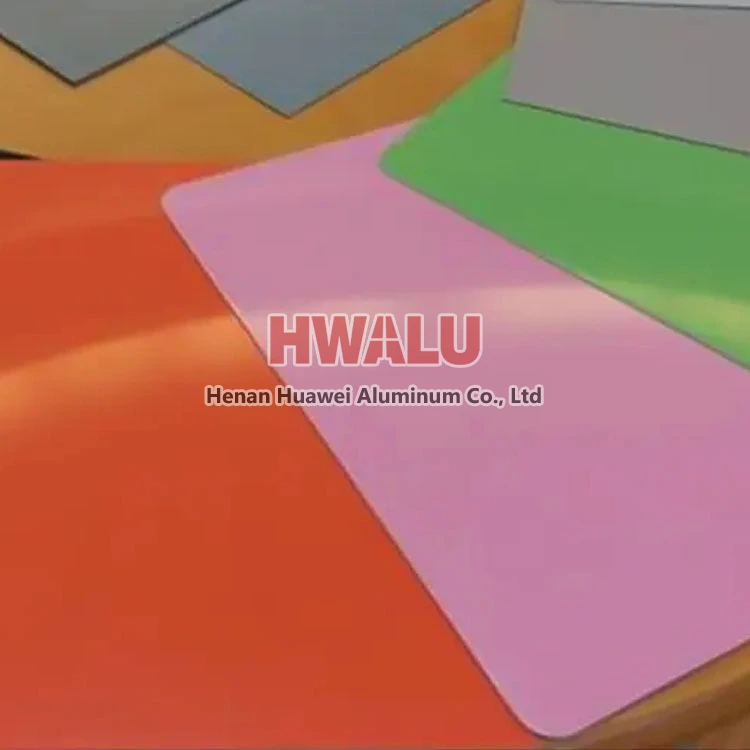

What is color coated aluminum sheet Color coated aluminum sheet is a kind of aluminum plate with a coated surface, usually by applying one or more layers of organic paint on the surface of the aluminium plate, and then curing it by heating it to form a layer of wear-resistant, anti-corrosion, and anti-ultraviolet color coating. layer. This aluminum plate not only has excellent corrosion resistance and wear re ...

14 gauge aluminum sheet product 14 gauge aluminum sheet is a way of expressing the specifications of the aluminum sheet. The 14 gauge aluminum sheet refers to the thickness of the sheet. The gauge system is used to specify the thickness of metal sheets, with smaller gauge numbers indicating thicker sheets. What is the thickness of 14 aluminum plate? Aluminum sheet 14 gauge thickness is approximately 0.0641 inc ...

Generally speaking, in the traditional concept, imported goods will be better than domestic ones. For example, for 5005 aluminum sheet that need to be used, people will think that imported aluminum sheets will be better than domestic ones, and the price is also higher. Actually, this concept is biased, the aluminum sheet industry is not the same as other industry, the price of 5005 aluminum sheet is affected b ...

Insulation aluminum plates are commonly used in daily life. Mainly used to manufacture thermal insulation equipment. The material is thermal insulation aluminum plate, which not only has the thermal insulation effect, but also is not easy to be damaged and has a long service life. Therefore, the actual value of the thermal insulation aluminum plate is very high. However, there are many insulating aluminum panels ...

6063-T6 aluminum is 6063 aluminum in the T6 temper. To achieve this temper, the metal is solution heat-treated and artificially aged until it meets standard mechanical property requirements. The graph bars on the material properties cards below compare 6063-T6 aluminum to: 6000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the re ...

The applications of automotive aluminum sheet increased significantly The latest research shows that the future demand for aluminum sheets will grow at an unprecedented rate. 2014 and 2015 are considered a turning point in the automotive industry from traditional steel to aluminum and other lightweight materials, including the use of aluminum instead of advanced high strength steel (AHSS). I ...

Summer is the time when aluminum products such as aluminum plates, aluminum coils, and aluminum strips are exposed to water corrosion and oxidation. Although there is a classification of aluminum oxide plates in aluminum plate products, the oxidation of aluminum oxide plates and aluminum plates are completely different things. The difference between alumina plate and aluminum plate oxidized: 1. Alumina plate g ...

Alloy 7075 has been thoroughly evaluated for corrosion resistance of atmospheric weathering, stress-corrosion cracking and exfoliation in all currently available tempers. These values have been used as a standard for comparison in the development of more recent high strength aerospace alloys and used for highly stressed structural parts in the aerospace and defense industries, and as mold material in the plastics ...