What are the two types of aluminum anodizing? There are two main types of aluminum anodizing: sulfuric acid electrolytic oxidation and hard anodizing. Sulfuric acid electrolytic oxidation is a conventional anodic oxidation method, which uses sulfuric acid as the electrolyte to form an oxide film on the surface of aluminum by means of electricity. This oxide film has certain protective and decorative propertie ...

What is embossed aluminum sheet plate? What is embossed aluminum? Embossed aluminum plate, also known as aluminum embossed plate, is an aluminum product that is formed on the surface with various patterns on the surface through rolling processing based on the aluminum plate. Embossed aluminum sheet not only has the basic characteristics of aluminum sheets, such as light weight, corrosion resistance, easy process ...

Understanding 0.25 Inch aluminum sheets 0.25 inch aluminum sheet, also known as a quarter-inch aluminum sheet, is a standard thickness for aluminum plates. 0.25 inch aluminum sheet is also called 1/4 inch aluminum sheet, converted to mm is 6.35mm, which is a medium-thick plate. The importance of choosing the right thickness Choosing the right thickness for an aluminum sheet, or any material, is crucial ...

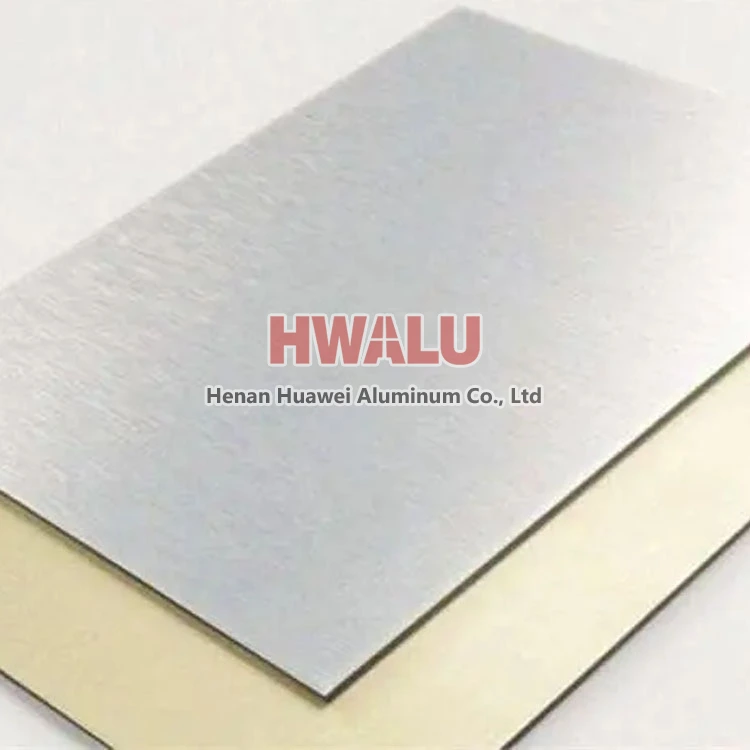

Aluminium Composite Panel (ACP) is a type of flat panel that consists of two thin aluminium sheets bonded to a non-aluminum core. ACP is used within the signage industry as an alternative to heavier, more expensive substrates. ACP is also used for external and internal architectural cladding or partitions, false ceilings, machine coverings, container construction, etc Composition and function As a new type ...

3005 Aluminum sheet overview 3005 alloy metal aluminum sheet plate belons to aluminium sheet 3xxx series. The strength of 3005 al-mg aluminum plate is about 20% higher than that of 3003 aluminum plate, and corrosion resistance is also better.Also known as anti-rust aluminum plate. 3 series aluminum plate is mainly composed of manganese, with the content between 1.0 and 1.5.It is a series with better anti-rust ...

Forging 6063 aluminium sheet coil can be done using a temperature set between 750 and 900 degrees Fahrenheit. Temperatures to use for hot working should be between 500 and 700 degrees Fahrenheit. Any common welding technique can be used for this metal. If annealing is needed, it should be performed continuously at 775 degrees Fahrenheit for between two and three hours, then provide controlled cooling at 50 deg ...

With the continuous development of technology, the application range of aluminum sheet has been very extensive, designing buildings, ships, aviation, electrical appliances and other fields. Aluminum sheet and aluminum strip product is also a common material for making lamp holders. Brass is often nickel-plated to achieve high corrosion resistance as a material for lamp bases, but brass at higher cost, china 30 ...

3004 aluminum alloy is an alloy in the wrought aluminium-manganese family (3000 or 3xxx series). It is similar to the 3003 alloy, except for the addition of approximately 1% magnesium. It can be cold worked (but not, unlike some other types of aluminium alloys, heat treated) to produce tempers with a higher strength but a lower ductility. Like most other aluminium-manganese alloys, 3003 is a general-purpose alloy ...

The unevenness of the aluminum plate is caused by 40% of the material and 60% of the construction. In fact, every aspect is indispensable. main reason: 1. Deepening the design Folding size: The conventional folding size of the aluminum sheet factory is 20mm, but in the project design, due to the façade effects such as deep grooves, the designer usually directly widens the folding size, or even folds ...

5052 H32 Aluminum Sheet - Superior corrosion resistance, good weldability, with excellent formability, makes 5052 Aluminum Sheet a common choice for chemical, marine or saltwater applications. 5052 Aluminum Sheet applications include: tanks, marine hardware, boat hulls, etc. What's the Application of 5052 aluminum sheet? Building, curtain wall, ceiling, panels, transformers, food packaging, air conditioning, ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...