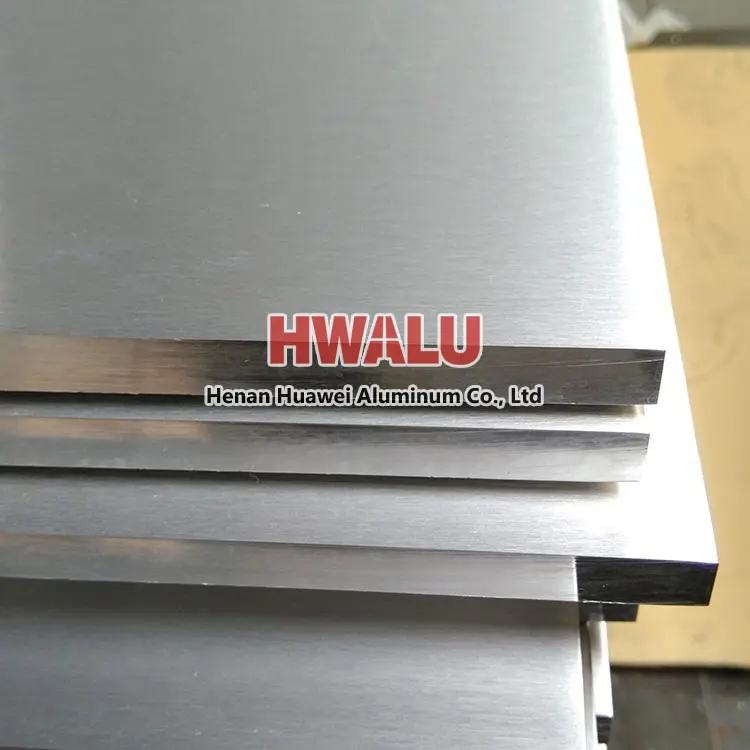

Introduction to 3004 aluminum sheet/plate? 3004 aluminum sheet is a non-heat-treatable aluminum alloy with manganese as its primary alloying element. It is similar to 3003 except for the addition of approximately 1% magnesium. It can be used to produce tempers with a higher strength but a lower ductility. 3004 series also belongs to a series of aluminum manganese alloy. It has higher strength than 3003, exce ...

What does the 4x8 in the 4x8 foot aluminum plate mean? In general, 1'=1 foot (symbol ft) = 12 inches (12") = 30.48 cm = 304.8 mm 1"=1 inch ( inch is abbreviated as in or " ) = 2.54 cm = 25.4 mm (actual value is 2.539999918 cm.) So, 4 in 4 x 8 foot is 4 x 304.8 mm = 1219.2 mm = 1.2192 m ≈ 1220mm ≈ 1.22 m 8 in 4 x 8 feet is 8 x 304.8 mm = 2438.4 mm = 2.4384 meters ≈ 2440mm ≈ 2.44 m i.e. 4x8 foot = 1.22m ...

How is embossed aluminum sheet produced Select aluminum material: first select the aluminum plate that meets the requirements. Commonly used aluminium materials include aluminum alloy plate, pure aluminum plate, etc., and their thickness is generally between 0.5mm-3mm. Surface treatment: The surface of the aluminium plate is cleaned, degreased, pickled, etc. to remove impurities such as oil and scale to e ...

What is polished aluminum sheet? Polished aluminum plate is a high-gloss aluminum plate with a polished and oxidized surface. Polished aluminum sheet is usually an aluminum sheet that is processed by rolling, polishing and other methods to give the surface of the sheet a mirror effect. This treatment can not only improve the surface finish and corrosion resistance of the aluminum plate, but also remove oxides an ...

5454 Alloy Metal Aluminum Sheet Plate Features Al 5454 is non-heat-treatable aluminum and magnesium alloy. It is a medium-strength alloy that can be hardened (strengthened) by cold work; It is commonly used to manufacture welded structures, pressure vessels, and Marine services. The machining performance of Al 5454 is not satisfactory. It is best to use H-34 temper alloy processing. Oil-based lubricants a ...

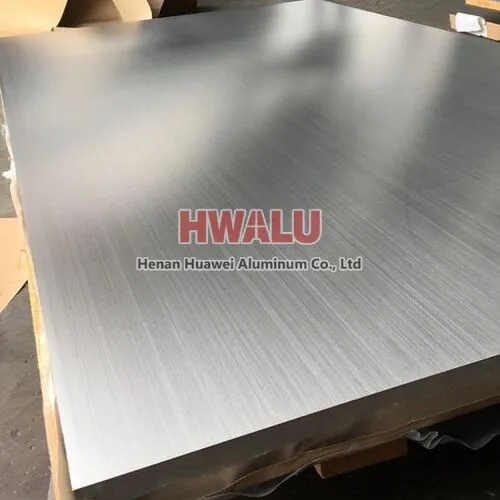

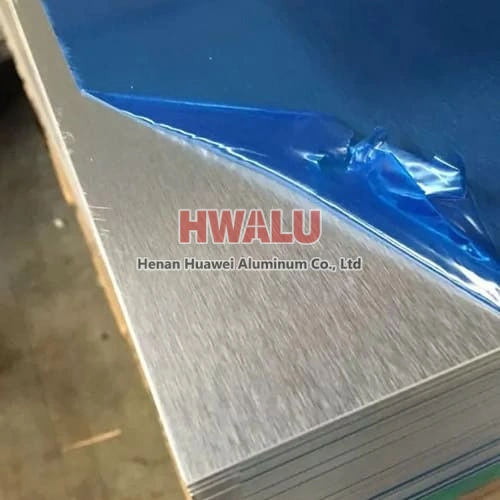

What is brushed aluminum sheets Brushed aluminum sheets are aluminum sheets that have a brushed finish applied to them. This finish is achieved by mechanically brushing the surface of the aluminum with a fine abrasive material. The brushing process creates a distinctive pattern of fine lines on the surface, giving the aluminum a stylish, modern look. Brushed aluminum sheets are commonly used in interior a ...

5005 h24 aluminum alloy is an aluminium alloy with good resistance to atmospheric corrosion.It is used in decorative and architectural applications. It is a member of the 5000 series of aluminum-magnesium wrought alloys. As such, it is not used in casting. It can attain moderate to high strength by cold working, and has relatively high welded strength compared to other aluminum alloy families. Tempers H116 and H3 ...

There are many anodic oxidations for aluminum alloys, which can be used in daily life. Because of the characteristics of this process, a hard protective layer is produced on the surface of aluminum parts, which can be used to produce kitchen utensils and other daily necessities. However, the anodizing effect of cast aluminum is not good, the surface is not good, and it can only be black. The aluminum alloy profil ...

7005 aluminum alloy is used bicycle frames, due to its relative ease of welding it does not require expensive heat treating - it is however harder to form making manufacture more challenging. It has an Ultimate Tensile Strength of 350MPa, a Fatigue Strength of 150MPa and a density of 2.78g/cm³ compared to a Ultimate Tensile Strength of 310MPa and Fatigue Strength of 96.5 MPa and a density of 2.70g/cm³ for 6061 al ...

Chemical treatments: There are several commercial products available that can be applied to corrugated metal to give it an aged look. One popular product is called "Instant Rust," which can be sprayed onto the metal to create a rusted patina. Other options include vinegar, saltwater, and bleach solutions that can be applied to the metal to promote rust or corrosion. Natural weathering: You can also age cor ...

3105-H14 aluminum is 3105 aluminum in the H14 temper. To achieve this temper, the metal is strain hardened to a strength that is roughly halfway between annealed (O) and full-hard (H18). The graph bars on the material properties cards below compare 3105-H14 aluminum to: 3000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relev ...

What is Colored mirror polished aluminium sheet?The application of mirror polished aluminium sheet is constantly being carried out with continuous development of technology. With the level improvement of peoples life, there are many new applications of mirror aluminium sheet, and the colored aluminum mirror sheet is one kind of them. The color aluminum mirror sheet has better decoration effect than ordinary mirr ...