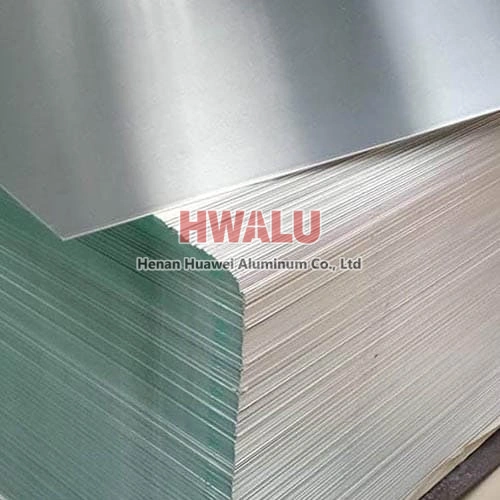

What is 050 aluminum sheet The 050 aluminum sheet refers to an aluminum sheet with a thickness of 0.05 inches, which is equivalent to 1.27 millimeters. It’s a common material used in various industrial manufacturing and household applications due to its strength, light weight, and corrosion resistance. Specifications for the 050 aluminum sheet Alloy Types: 1000, 3000, 5000, 6000 series Temper: O, H12, ...

What is the cold rolling aluminium sheet? Cold rolling of aluminum sheets is usually carried out on a four-high or six-high mill. The cold rolling process of aluminum sheets is generally divided into rough rolling, intermediate rolling, and finishing rolling. Rough rolling and intermediate rolling focus on increasing pressure, strengthening the production process, and shortening the production cycle. The visc ...

Parameters of aluminum sheet plate for a trailer Alloy Temper Length Thickness(mm) Width(mm) Color Finish Painted sheets 1100、1060 3003 5052、5754 6061、6063、6082 H*2、H*4、T4、T6 Variable 1.0-8.0 20-1850 White\Black\Grey\Red\Pewter\Silver Painted Diamond Tread Plate White\Black\Red one-side-bright What are the reasons for choosing aluminum over steel for trailers? ...

Construction with aluminum veneer where to buy? Why do architects prefer anodized aluminum? ① Good processability: anodized aluminum plate decorative strong, moderate hardness, easy bending molding, continuous high-speed stamping, convenient direct processing into products, no need to carry out complex surface treatment, greatly reduce the production cycle and reduce product production costs. (2) Good wea ...

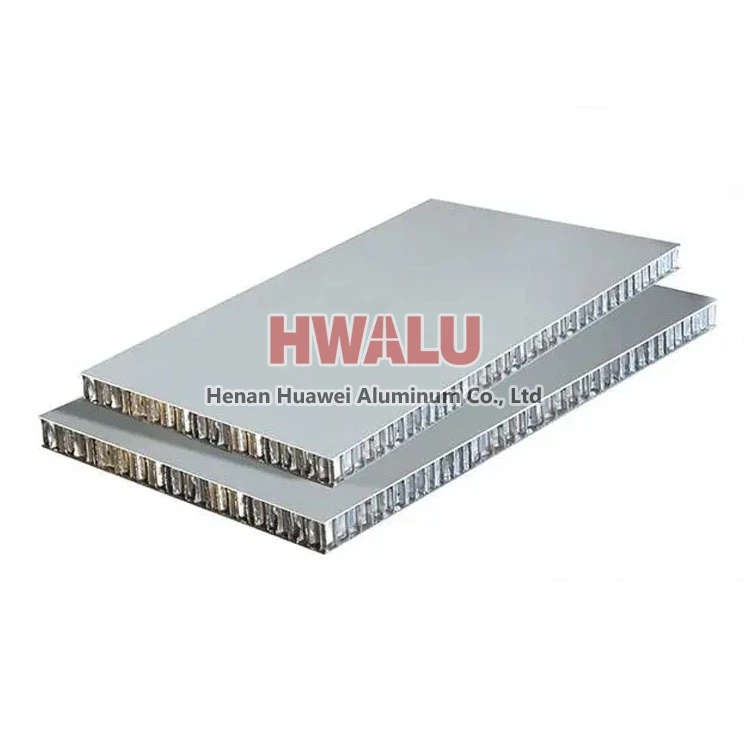

What is Honeycomb Aluminum Panel Honeycomb Aluminum Panel is an aluminum panel with a regular honeycomb structure, also known as honeycomb aluminum core panel or aluminum-plastic panel. It consists of two layers of metal outer plates and a middle honeycomb aluminum core layer. The middle honeycomb aluminum core layer is composed of many hexagonal honeycomb sections. These hexagonal honeycomb sections are connect ...

What is embossed aluminum sheet plate? What is embossed aluminum? Embossed aluminum plate, also known as aluminum embossed plate, is an aluminum product that is formed on the surface with various patterns on the surface through rolling processing based on the aluminum plate. Embossed aluminum sheet not only has the basic characteristics of aluminum sheets, such as light weight, corrosion resistance, easy process ...

Aluminum Alloy 6061 sheets are the most versatile of the heat treatable aluminum alloys. Though less strong than most of the 2000 and 7000 alloys, 6061 aluminum provides an extensive range of mechanical properties and corrosion resistance and can be fabricated by many of the commonly used practices. In the ""O"" temper or annealed condition, alloy 6061 has good formability. In the T4 condition, fairly severe form ...

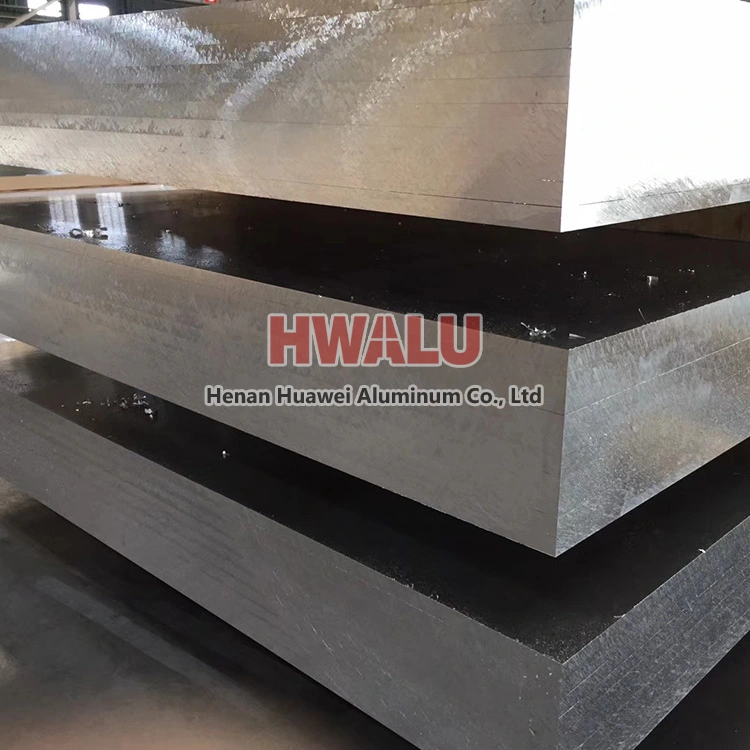

Among the 1000 to 8000 alloy series, the 7000 series aluminum alloy is a heat treatable alloy, belonging to the aircraft series, and belongs to a relatively high-end field in aluminum sheets. The 7075 aluminum sheet is a representative product of the 7000 series, it is aircraft aluminum sheet with aluminum magnesium zinc copper alloy, can be heat treatable, has super hard ability and good wear resistance.7075 ...

The high quality dc cc produced aluminum sheet alloy 3003 is a representative rust-proof aluminum alloy of AI-Mn. Due to the addition of manganese, the 3003 aluminum alloy is stronger and more resistant to corrosion than pure aluminum. The 3000 series aluminum-manganese alloy is a non-reinforced aluminum alloy that has undergone heat treatment because it has excellent properties such as low density, good plast ...

Both 7005 aluminum and 6061 aluminum are aluminum alloys. They have a moderately high 95% of their average alloy composition in common. For each property being compared, the top bar is 7005 aluminum and the bottom bar is 6061 aluminum. Aluminum alloys are highly resistant to corrosion. They are sensitive to high temperatures ranging between 200 and 250°C (392 and 482°F), and tend to lose some of their strength ...

3003 H14 Aluminum Sheet is alloyed with 1.2% maganese to provide a tensile strength range of 17 to 30 KSI. 3003 has Excellen workability, weldability, and corrosion resistance. the 5052 aluminum alloy is used to make beverage closure without internal pressure. The raw material is 5052 H19 aluminum sheet, the material is first oxidized to improve the coating adhesion and corrosion resistance. After the two side ...

Scratches on the surface of aluminum plates are more likely to occur in the process of aluminum plate processing. It is often caused by improper processing and treatment, which causes the surface to be damaged, which seriously affects the aesthetics of the aluminum plate. However, the scratches have already appeared. The following describes the surface scratch treatment of the aluminum plate. method. The surface ...