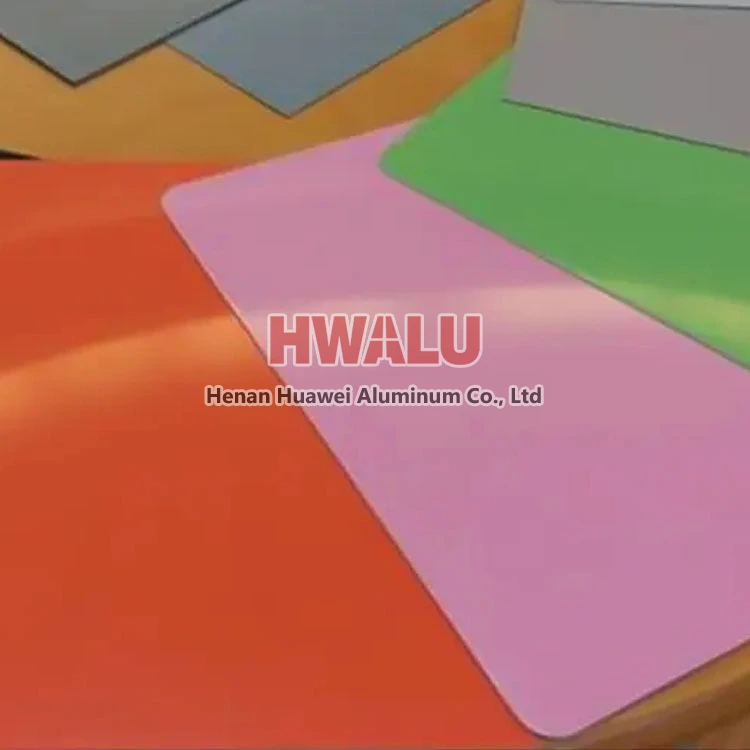

What is color coated aluminum sheet Color coated aluminum sheet is a kind of aluminum plate with a coated surface, usually by applying one or more layers of organic paint on the surface of the aluminium plate, and then curing it by heating it to form a layer of wear-resistant, anti-corrosion, and anti-ultraviolet color coating. layer. This aluminum plate not only has excellent corrosion resistance and wear re ...

what is 6000 series aluminum sheet? 6 series aluminum alloy mainly contains two elements of magnesium and silicon, also known as "aluminum-magnesium-silicon alloy", is a heat treatment type of corrosion-resistant aluminum alloy, with high strength and corrosion resistance, good uniformity, excellent processing performance, excellent welding characteristics and plating, good corrosion resistance, high toughness a ...

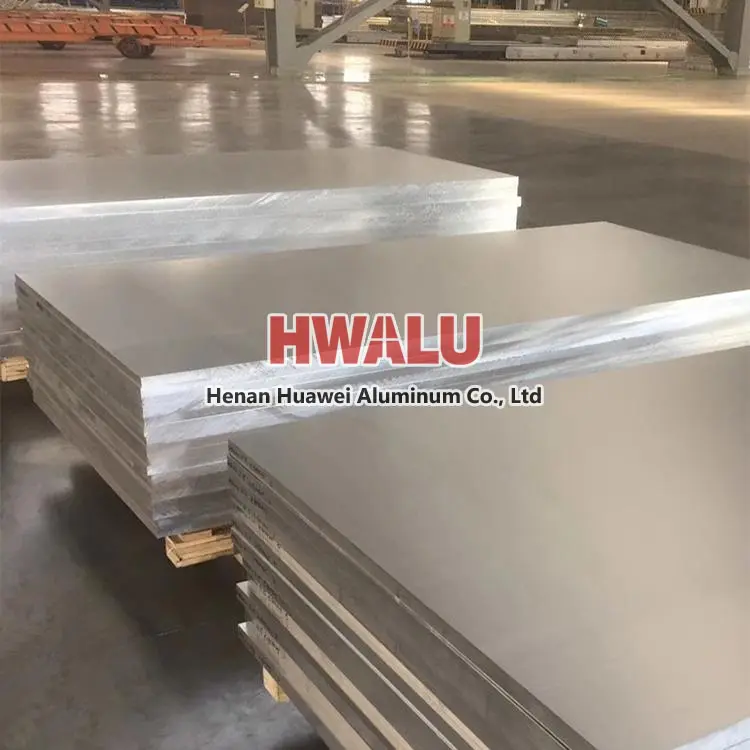

Definition of 4mm aluminum sheets A 4mm aluminum sheet, also known as an aluminum plate, is a panel of aluminum that is 4 millimeters thick. It’s a result of basic raw-form aluminum being pressed and rolled into panel form under high pressure. Aluminum sheets are characteristically manufactured to be very thin and lightweight, yet sturdy enough to offer extreme versatility alongside inherent ease of installat ...

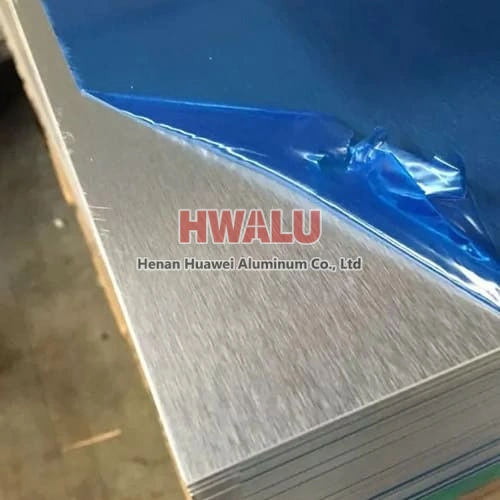

What is brushed aluminum sheets Brushed aluminum sheets are aluminum sheets that have a brushed finish applied to them. This finish is achieved by mechanically brushing the surface of the aluminum with a fine abrasive material. The brushing process creates a distinctive pattern of fine lines on the surface, giving the aluminum a stylish, modern look. Brushed aluminum sheets are commonly used in interior a ...

5454 Alloy Metal Aluminum Sheet Plate Features Al 5454 is non-heat-treatable aluminum and magnesium alloy. It is a medium-strength alloy that can be hardened (strengthened) by cold work; It is commonly used to manufacture welded structures, pressure vessels, and Marine services. The machining performance of Al 5454 is not satisfactory. It is best to use H-34 temper alloy processing. Oil-based lubricants a ...

Ⅰ: Aluminium sheet price list Date:Based on April 1st,2022-March 28th ,2022 LME Weekly Average Price 3545 USD No. "Thickness mm" "Width*Length feet/mm" "MOQ ton" " FOB usd/ton" 1 0.2-0.29 3.27'*6.55'(1000*2000mm) 6.00 3805.00 3.93'*7.86(1200*2400mm) 8.00 4'*8'(1220*2440mm) 8.00 4.09'*8.19'(1250*2500mm) 8.00 4.91'*9.83'(1500*3000mm) 10.00 2 0.3-0.39 Same As A ...

3003 aluminum plate and 5052 aluminum plate are the most common alloy aluminum plates on the market, and are the two most representative grades of the two series of aluminum plates. Although they are widely used, many people do not know the difference between the two. Below, take 3003H24 aluminum plate and 5052H24 aluminum plate as examples to popularize this knowledge for everyone. From the chemical compositi ...

What is the difference between 6061 T5 and 6061 T651 aluminum sheet? The 6000 series represents 6061 aluminum, which contains mainly magnesium and silicon. It is a cold-treated aluminum forging product with the advantages of 4000 Series and 5000 Series. The difference between the state T6 and T651 of 6061 aluminum sheet is that the internal stress of T6 is relatively large and the processing will be deformed ...

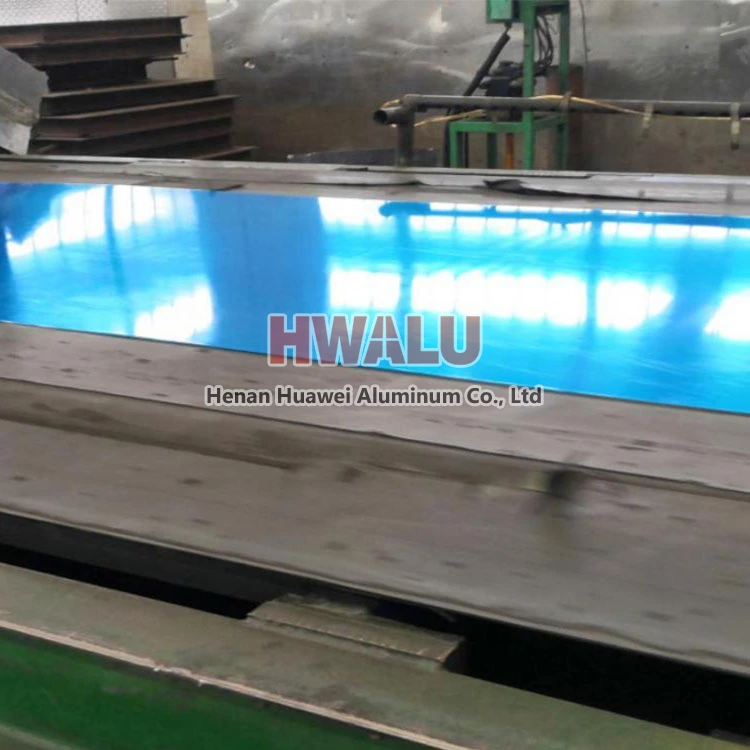

How to distinguish the quality of aluminum sheet? The surface of the aluminum sheet is not allowed to have cracks, corrosion, cracked edges, and the surface of the aluminum sheet with a thickness of more than 0.6mm is not allowed to have diffusion spots. The surface of the aluminum sheet is allowed to have defects such as slight pressure scratches, metal and non-metal indentations, insertion marks, scratches, ro ...

1100 aluminum plate sheet for industrial pure aluminum, aluminum content (mass fraction) of 99%, non heat treatment. It has high corrosion resistance, electrical conductivity and thermal conductivity, low density, good plasticity, and can be used to produce all kinds of aluminum, but the strength is low. Other processes are basically the same as 1050A. 1100 aluminum sheet commonly used to have good machining perf ...

3003 rolled aluminum sheet are usually applied as the insulation material for pipe and the construction industry. In the new era, the construction industry has more and more requirements for the raw materials, the performance requirements of building materials must not only have aesthetics, durable performance, but also have certain insulation properties, especially in the cold regions. Due to the influence of ...

7075-T6 Aluminum Sheet is primarily used in aerospace industry, often referred to as the Strongest Aluminum grade. Alloy 7075 has the strength of many steels, while retaining aluminum’s lightweight qualities. 7075 aluminum sheet is one of the highest strength aluminum alloys available Its strength-to weight ratio is excellent and it is ideally used for highly stressed parts. It may be formed in the annealed co ...