Specifications of 6005 aluminum plate Alloy 6005 Aluminum Sheet Temper O, T4, T6, T651 Thickness(mm) 0.3-600 Width(mm) 500-2600 Length(mm) customized Typical products Car fuel tank, Traffic vehicles 6005 Aluminum Sheet Chemical Composition Elements Al Cr Cu Fe Mg Mn Si Ti Zn Others Content (max) 97.5 to 99.0% 0.1% 0.1% 0.35% 0.4 to 0.6% ...

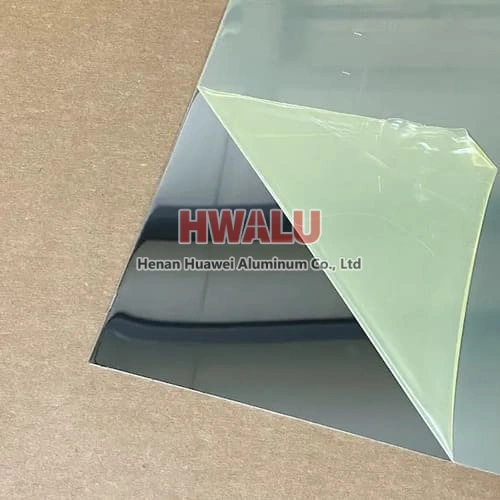

What is reflective aluminum sheet? What is aluminum sheet reflector? Reflective aluminum sheet, also known as mirror aluminum sheet or reflective aluminum, is a type of aluminum sheet. It has reflective surfaces that reflect light and heat. It has high reflectivity, also known as high reflective aluminum sheet. Reflective aluminum sheet refers to a thin and flat aluminum material that has been specially treated ...

Introduce you to 2014 aluminum sheet 2014 aluminum sheet alloy elements for the copper, known as hard molybdenum, with high strength and good cutting processing performance; 2014 aluminum sheet used in the requirements of high strength and hardness (including high temperature) of the occasion, also known as 2 military aluminum ; 2014 aluminum sheet application: heavy forgings, thick plates, and ex ...

Construction with aluminum veneer where to buy? Why do architects prefer anodized aluminum? ① Good processability: anodized aluminum plate decorative strong, moderate hardness, easy bending molding, continuous high-speed stamping, convenient direct processing into products, no need to carry out complex surface treatment, greatly reduce the production cycle and reduce product production costs. (2) Good wea ...

What is perforated aluminum sheet? Perforated aluminum sheet is punched on the aluminum plate with professional CNC equipment on a variety of perforated aluminum sheets, called perforated aluminum sheets After punching all kinds of holes through bending machine edge pressing, appearance to do fluorocarbon, or powder spraying, do not let the aluminum plate natural oxidation, or for beauty, do a variety of favori ...

Understanding 0.25 Inch aluminum sheets 0.25 inch aluminum sheet, also known as a quarter-inch aluminum sheet, is a standard thickness for aluminum plates. 0.25 inch aluminum sheet is also called 1/4 inch aluminum sheet, converted to mm is 6.35mm, which is a medium-thick plate. The importance of choosing the right thickness Choosing the right thickness for an aluminum sheet, or any material, is crucial ...

The 7000 series aluminum is the strongest material in 8 series aluminum alloys. In particular, the 7075 aluminum plate is a super-hard aluminum, which is the ideal material for manufacturing aircraft. The price of 7075 aluminum is relatively higher than pure aluminum, so it is generally used for aviation. 7075 aluminum covers the advantages of 7000 series aluminum.The 7000 series aluminum alloy can be regarded ...

3003 H14 Aluminum Sheet is alloyed with 1.2% maganese to provide a tensile strength range of 17 to 30 KSI. 3003 has Excellen workability, weldability, and corrosion resistance. Aluminum sheet 5052 is used in many types of industrial applications, including: Refrigerator liners Fuel tanks Storm shutters Panels 6061 aluminum sheet alloy is strong, easily machined, and weldable. Aluminum 6061 T6 alloys are dou ...

5005 h24 aluminum alloy is an aluminium alloy with good resistance to atmospheric corrosion.It is used in decorative and architectural applications. It is a member of the 5000 series of aluminum-magnesium wrought alloys. As such, it is not used in casting. It can attain moderate to high strength by cold working, and has relatively high welded strength compared to other aluminum alloy families. Tempers H116 and H3 ...

There are many anodic oxidations for aluminum alloys, which can be used in daily life. Because of the characteristics of this process, a hard protective layer is produced on the surface of aluminum parts, which can be used to produce kitchen utensils and other daily necessities. However, the anodizing effect of cast aluminum is not good, the surface is not good, and it can only be black. The aluminum alloy profil ...

Aluminum 3105 alloy sheet has good forming characteristics. It is suggested that bend radii should be used in one thickness to 2 t range for annealed H12, H14 and H16 tempers. Bend radii of 2 to 7 t should be used for the H18 temper. Due to its physical properties aluminum sheet & plate is valued and sought after choice metal for many different industrial applications, some of which include: Roofing Gutter ...

2024 aluminium alloy sheet is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has average machinability. Due to poor corrosion resistance, it is often clad with aluminium or Al-1Zn for protection, although this may reduce the fatigue strength. ...