Alloy properties of 5000 series aluminum sheets The 5000 aluminum plate series is a commonly used alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as an aluminum-magnesium alloy. Its main features are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloys in the same area is lower than other series, so it i ...

What is the size of 0.187 inch aluminum sheet? 0.187 is the thickness of the aluminum plate, representing 0.187 inches thick. Aluminum sheet thickness 0.187 is a common thickness found in industries such as construction, manufacturing, automotive, aerospace, and craft. 0.187 inch aluminum sheet thickness 0.187-inch aluminum sheet refers to an aluminum sheet with a thickness of 0.187 inches (or about 3/16 i ...

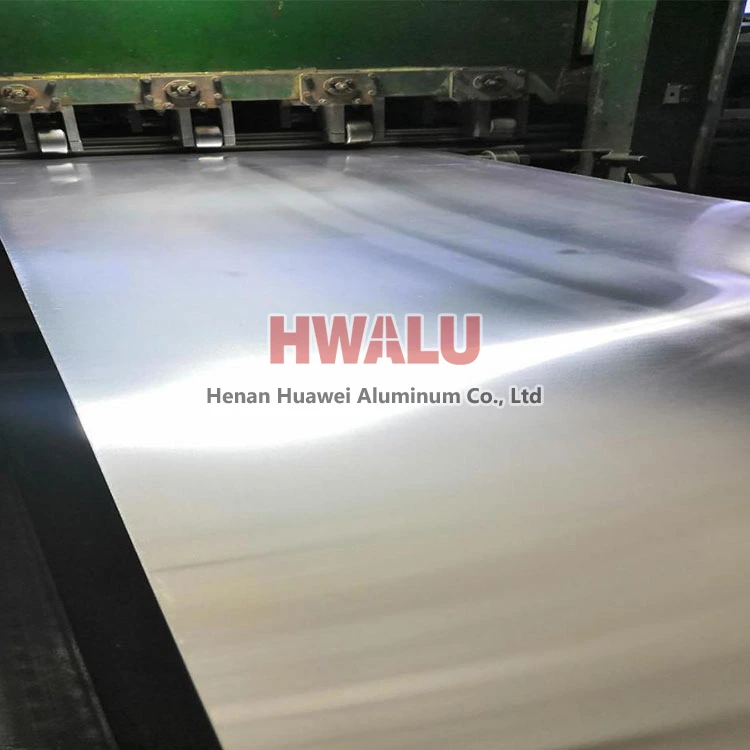

What is hot rolling? Hot rolling generally refers to rolling above the recrystallization temperature of the metal. During the hot rolling process, the metal deformation has both hardening and softening processes. Due to the influence of the deformation speed, as long as the recovery recrystallization process is too late, the metal will have a certain degree of work hardening with the increase of the deformation ...

14 gauge aluminum sheet product 14 gauge aluminum sheet is a way of expressing the specifications of the aluminum sheet. The 14 gauge aluminum sheet refers to the thickness of the sheet. The gauge system is used to specify the thickness of metal sheets, with smaller gauge numbers indicating thicker sheets. What is the thickness of 14 aluminum plate? Aluminum sheet 14 gauge thickness is approximately 0.0641 inc ...

what is 7075 aluminum sheet? 7075 alloy metal aluminum sheet plate is a common alloy in 7000 series aluminum alloy sheet. 7075 aluminum sheet (Al-Zn-Mg-Cu) belongs to super-hard aluminum. As a kind of cold finished wrought alloy, it has great strength and hardness. It’s far better than mild steel. This alloy has good mechanical properties and anode reaction. 7075 aluminum sheet as a typical kind of aerospace al ...

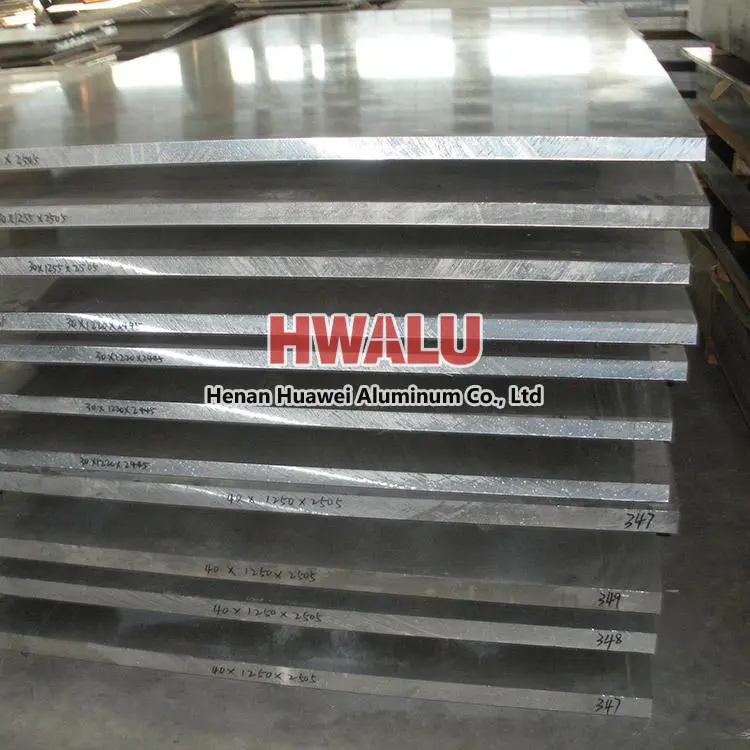

Aluminum sheet plate refers to aluminum material with a thickness of 0.2mm over to less 500mm. Classification by thickness Thin aluminum sheet plate Standard thickness aluminum sheet plate Medium thickness aluminum plate Thick aluminum sheet plate Super thick aluminum sheet plate Different thickness aluminum sheet determines its different functions. And different functions can be used in diff ...

2024 aluminium alloy sheet is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has average machinability. Due to poor corrosion resistance, it is often clad with aluminium or Al-1Zn for protection, although this may reduce the fatigue strength. ...

Divided by use: 1. Aluminum-plastic panels for building curtain walls: the minimum thickness of the upper and lower aluminum panels is not less than 0.50mm, and the total thickness is not less than 4mm. The aluminum material should meet the requirements of GB/T according to 3880. Generally, 3000 and 5000 series aluminum alloy plates are coated with fluorocarbon resin. 2. Aluminum-plastic panels are used for ...

Aluminium 3004 alloy belongs to the 3000 series aluminum, mainly composed of manganese element as the other alloy content. It is a more commonly used alloy with good rust resistance. The most widely used in buildings is the 3000 series “aluminum-manganese alloys of which the 3003, 3004, 3005, 3103 and 3105 alloys are used in large quantities, because the manganese content in the aluminum-manganese alloy is sta ...

Aluminum-manganese alloy mirror aluminum sheet 3003 has good performance in rust resistance and corrosion resistance. Anyone who knows mirror aluminum sheets knows that there are many specific varieties in terms of materials and crafts. From the material point of view, there are three main types, the pure aluminum mirror sheet, the Al-Mn aluminum mirror sheet and Al-Mg mirror aluminum sheet, among them, the al ...

5052 aluminum sheet, mainly for the magnesium alloy element which have a good forming performance, corrosion resistance, weldability and medium strength, used to make airplane oil tank, oil pipe, as well as the transportation vehicles, ships, sheet metal parts, instrument, lamps stent and rivet, metal products, electrical enclosure, etc.5052 aluminum sheet, with thickness more than 6mm and magnesium content betwe ...

Marine grade aluminum sheet are applied in processing large boats, yachts and other ships,and dnv approved aluminum sheet 5083 is professional anti-rust aluminum plate. Compared with other industries, marine industry pay more attention to safety and quality in many aspects. Therefore, marine grade aluminum plates with excellent performance can be applied to more ship factories. Through the alloy composition de ...