5454 Alloy Metal Aluminum Sheet Plate Features Al 5454 is non-heat-treatable aluminum and magnesium alloy. It is a medium-strength alloy that can be hardened (strengthened) by cold work; It is commonly used to manufacture welded structures, pressure vessels, and Marine services. The machining performance of Al 5454 is not satisfactory. It is best to use H-34 temper alloy processing. Oil-based lubricants a ...

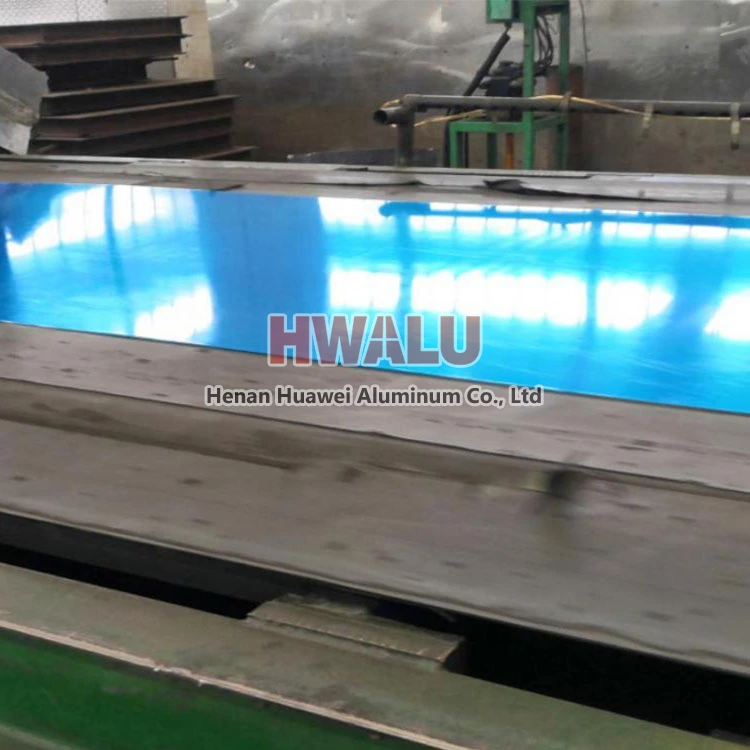

Premier 0.8mm Aluminum Sheet Factory and Wholesaler Introduction Welcome to Huawei Aluminum, your trusted source for high-quality 0.8mm aluminum sheets. Our precision-engineered sheets are crafted to meet the diverse needs of various industries, offering durability, versatility, and performance. Product Overview Our 0.8mm aluminum sheets come in a range of alloy models, each tailored for specific applic ...

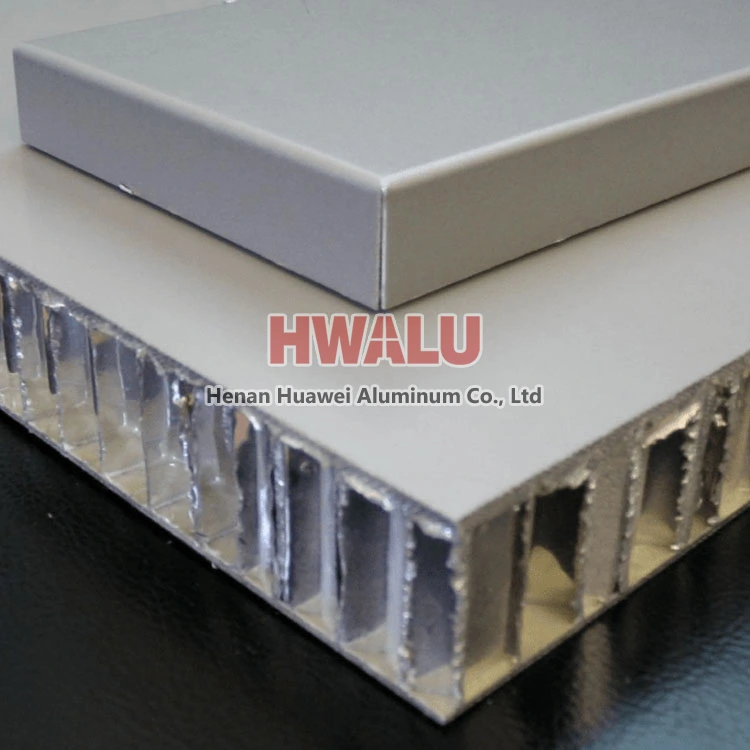

What is aluminum composite panel? Aluminum composite panel is a composite material made of aluminum and aluminum, such as: a honeycomb aluminum panel made of aluminum substrate and aluminum honeycomb core, which is a type of acm panels. Easy to process Aluminum composite panels can be machined using common woodworking or metalworking tools without special tools. It can be easily cut, slotted, punched, drilled, ...

what is 7075 aluminum sheet? 7075 alloy metal aluminum sheet plate is a common alloy in 7000 series aluminum alloy sheet. 7075 aluminum sheet (Al-Zn-Mg-Cu) belongs to super-hard aluminum. As a kind of cold finished wrought alloy, it has great strength and hardness. It’s far better than mild steel. This alloy has good mechanical properties and anode reaction. 7075 aluminum sheet as a typical kind of aerospace al ...

Welcome to Huawei Aluminum, your trusted manufacturer and wholesaler of high-quality Aluminium Floor Plates. Our products are designed to meet a wide range of industrial and architectural needs, offering durability, strength, and aesthetic appeal. Introduction Aluminium Floor Plates are widely used in various applications such as construction, automotive, aerospace, and marine industries. They are known for the ...

8000 Series Aluminum Sheet Overview Features: It belongs to aluminum-lithium alloy, and its main component is lithium, because lithium is the lightest metal in nature. When lithium is added to the aluminum sheet, it can effectively reduce the ratio of aluminum sheet, while ensuring the strength of the aluminum sheet. Purpose: Aluminum plates with bottle caps as the main function are also used in radiators, ...

1050 aluminum is industrial aluminum with AI content of not less than 99.5%. The 1050 aluminum alloy has the characteristics of good electrical conductivity, good thermal conductivity and beautiful appearance. Stucco embossed aluminum plate can also be called aluminum embossed sheet, it belongs to the aluminum plate products after rolling and forming a variety of patterns on the surface, it is widely used in p ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum sheet has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

1. how to cut thin aluminum sheet 2. how to cut thick aluminum plate 3. how to cut 1/8 aluminum sheet 4. how to cut aluminum sheet with angle grinder 5. how to cut aluminum sheet with circular saw 6. how to cut aluminum sheet at home Here are 5 methods for your reference 1, the use of high pressure water cutting, is now a more popular cutting technology, a more high-tech way. In use, the ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

3004-H34 aluminum is 3004 aluminum in the H34 temper. To achieve this temper, the metal is strain hardened, and then stabilized, to a strength that is roughly a quarter of the way between annealed (O) and full-hard (H38). It has the second highest ductility compared to the other variants of 3004 aluminum. The graph bars on the material properties cards below compare 3004-H32 aluminum to: 3000-series alloys (top), ...

7005 aluminum sheet can be stressed further before being permanently deformed. The post weld heat treating process known as “aging” is 600 degrees Fahrenheit as opposed to 6061 at over 900 degrees Fahrenheit, making it a simpler and quicker process. Most of the commercially available butted tubes are 7005. We offer material from a variety of producers including Dedacciai, Nova and custom pipes from TubePro. We al ...