5454 Alloy Metal Aluminum Sheet Plate Features Al 5454 is non-heat-treatable aluminum and magnesium alloy. It is a medium-strength alloy that can be hardened (strengthened) by cold work; It is commonly used to manufacture welded structures, pressure vessels, and Marine services. The machining performance of Al 5454 is not satisfactory. It is best to use H-34 temper alloy processing. Oil-based lubricants a ...

What are the two types of aluminum anodizing? There are two main types of aluminum anodizing: sulfuric acid electrolytic oxidation and hard anodizing. Sulfuric acid electrolytic oxidation is a conventional anodic oxidation method, which uses sulfuric acid as the electrolyte to form an oxide film on the surface of aluminum by means of electricity. This oxide film has certain protective and decorative propertie ...

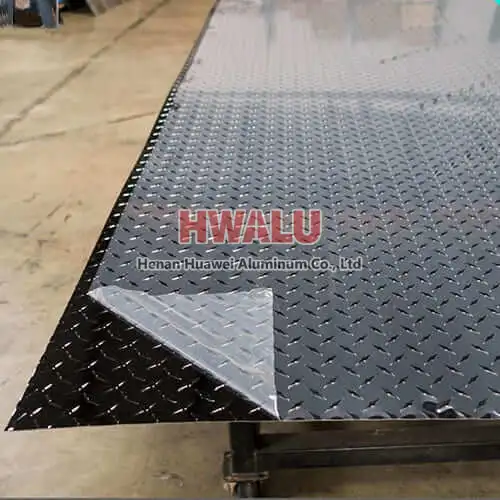

What is black aluminum checker plate Black aluminum checker plate, also known as black aluminum tread plate or black aluminum diamond plate, is an aluminum sheet with a raised diamond pattern on one side. This pattern provides slip resistance and is commonly used in various applications where traction and durability are required, such as truck beds, trailers, stairs, ramps, and industrial settings. The black ...

what is 5251 aluminum sheet? 5251 is a medium-strength metal known for its ductility and formability. This grade of Aluminium alloy is best known as a metal that can harden rapidly and is weldable easily. The 5251 alloy is also popular because of its high resistance to corrosion and is commonly used in marine, and coastal environments. 5251 Alloy Metal Aluminum Sheet Plate Description Aluminum 525 ...

What are the characteristics of 4017 aluminum plate? 4017 aluminum sheet plate has a variety of thicknesses and pattern sizes. 4017 aluminum alloy is a shiny surface similar to 3003. 4017 aluminum alloy provides durability. The constructed aging isotherm shows that EN 4017 with 0.19% Mg reaches a lower peak intensity than EN 4017 material with 0.43% Mg. The higher Mg variant of EN 4017 is comparable to the ag ...

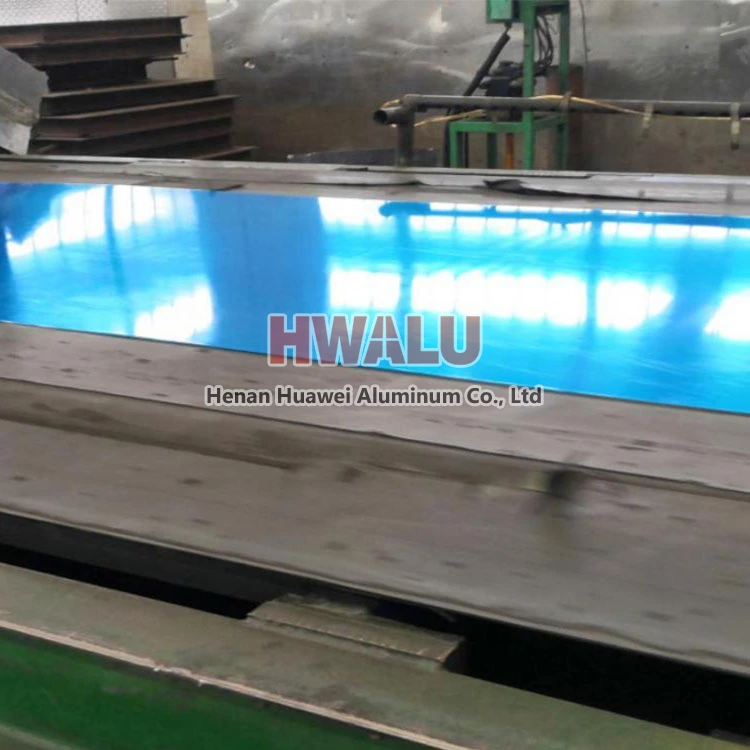

1050 metal aluminum sheet plate belongs to a commercially pure wrought family with a purity of 99.5% Aluminium( over 99.0% ). Except for Al, 0.4% of Fe is added to 1050 aluminum plates, thus, they have high electrical conductivity. 1000 series aluminum group offers the best correction resistance compared to any alloy group, and so does the 1050 aluminum sheet. 1050 aluminum sheet, temper O~H112, thickness ...

The processing cost of aluminum sheet and foil mainly includes the cost of natural gas, electricity, auxiliary materials, machinery depreciation, management expenses and so on. Natural gas is mainly used in the melting process of aluminum coil. The fuel consumption of liquid aluminum coil processing is 60 cubic meters per ton. The processing cost of a ton of aluminum coil in Henan increased by 114 yuan, and that ...

Aluminium Alloy 5754 H111 Sheets products designed for the aerospace and high-strength market, Commercial and structural application. Our expert team stringently checks these products on quality parameters to ensure flawless product range. Aluminium Alloy 5754 H111 Sheets has excellent corrosion resistance especially to seawater and industrially polluted atmospheres. It has higher strength and is typically use ...

7000 series aluminum alloy 7075 mainly contains zinc. It also belongs to the aviation series. It is an aluminum-magnesium-zinc-copper alloy, a heat-treatable alloy, and a supernatural alloy. It has good wear resistance and weldability, but poor corrosion resistance. Currently relying on imports, China's consumer technology needs to be improved. The 7075 is used to make aircraft structures and the future. He re ...

Classification: According to the combustion performance of the curtain wall panel, it is divided into ordinary type and flame-retardant type. The flame retardant type is divided into Class A and Class B according to the level of fire protection. Standard sizes: The common specifications and sizes of curtain wall panels are as follows: Length: The standard length is 2440. It can also be customized according ...

6082 aluminum alloy is another typical alloy of 6000 series aluminum, the common product are 6082 aluminum sheet and 6082 aluminum bar. Today we are going to talk about the first model- 6082 aluminum sheet. As we have in mind, 6000 series aluminum have Mg and Si as the main alloy besides Al, and 6000 series aluminum alloy is the most widely used aluminum product. So what are the features and application of 608 ...

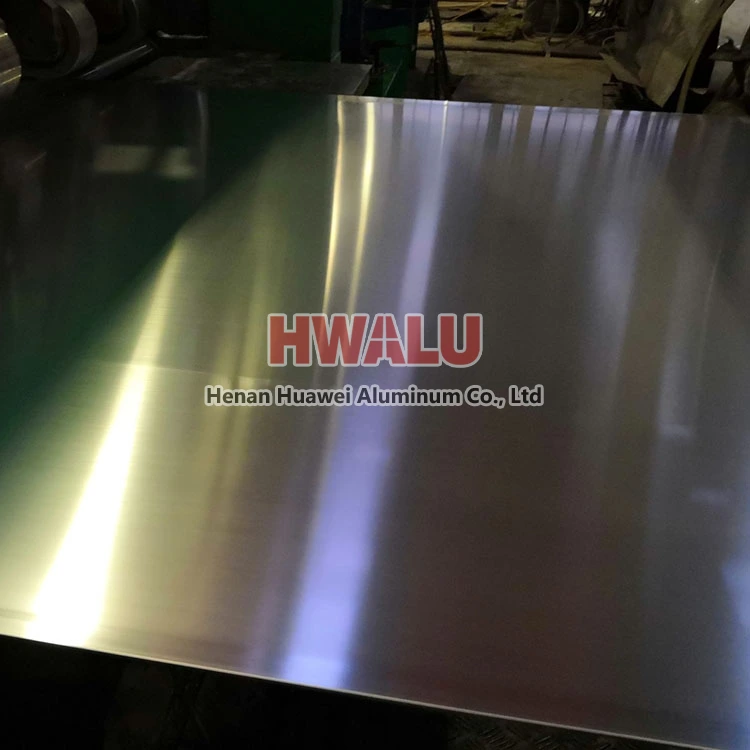

As a decorative material, the quality of mirror aluminum plates is particularly important, so users should pay special attention when purchasing mirror aluminum plates. Below, Huawei Aluminum Factory will introduce you to the selection criteria for mirror aluminum panels. 1. There are no cracks, corrosion, and edge cracks on the surface of the aluminum plate, and there is no diffusion spot on the surface of th ...