Introduction of 5086 aluminum sheet 5086 alloy metal aluminum sheet plate - an aluminum alloy with the primary alloy element being magnesium. It is not strengthened by heat treatment, instead becoming stronger due to strain hardening, or cold mechanical working of the material. Since heat treatment doesn't strongly affect the strength, 5086 can be readily welded and retain most of its mechanical strength. The go ...

What is "gauge" meaning for aluminuum sheet? In the context of aluminum sheets, “gauge” refers to the thickness of the sheet. It’s a standardized measurement system used to indicate the thickness of an aluminum sheet metal. There are two gauge systems used for aluminum sheets: American Wire Gauge (AWG): Ranges from 8 to 30, with the higher numbers indicating thinner sheets. Standard Wire Gauge (SWG): ...

0.5mm aluminum sheet brief description 0.5mm aluminum sheet is a common metal material in industry and manufacturing. Its basic feature is that it is a rectangular plate with a thickness of 0.5mm, which is rolled and processed from aluminum or aluminum alloy. Aluminum sheets of this thickness are lightweight, highly corrosion-resistant, have good electrical and thermal conductivity, and are widely used. Advanta ...

Specifications of 6005 aluminum plate Alloy 6005 Aluminum Sheet Temper O, T4, T6, T651 Thickness(mm) 0.3-600 Width(mm) 500-2600 Length(mm) customized Typical products Car fuel tank, Traffic vehicles 6005 Aluminum Sheet Chemical Composition Elements Al Cr Cu Fe Mg Mn Si Ti Zn Others Content (max) 97.5 to 99.0% 0.1% 0.1% 0.35% 0.4 to 0.6% ...

what is 2024 Alloy Metal Aluminum Sheet Plate? 2024 aluminum alloy is a high-strength aluminum alloy commonly used in the aerospace industry, as well as in other applications requiring a combination of high strength and good machinability. The alloy typically includes a small amount of copper as well as magnesium and is known for its excellent fatigue resistance. 2024 aluminum sheet and plate are available in ...

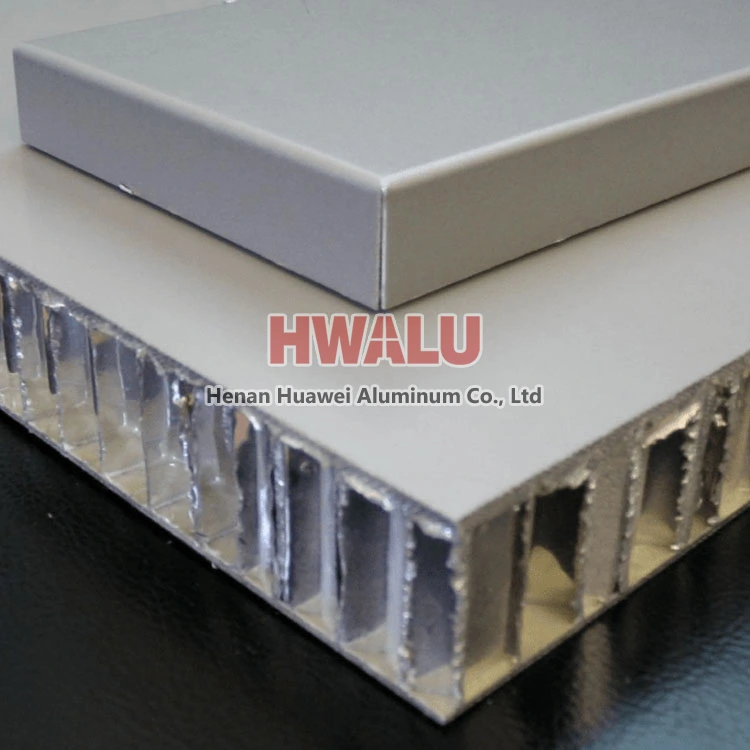

What is aluminum composite panel? Aluminum composite panel is a composite material made of aluminum and aluminum, such as: a honeycomb aluminum panel made of aluminum substrate and aluminum honeycomb core, which is a type of acm panels. Easy to process Aluminum composite panels can be machined using common woodworking or metalworking tools without special tools. It can be easily cut, slotted, punched, drilled, ...

With the continuous development of technology, the application range of aluminum sheet has been very extensive, designing buildings, ships, aviation, electrical appliances and other fields. Aluminum sheet and aluminum strip product is also a common material for making lamp holders. Brass is often nickel-plated to achieve high corrosion resistance as a material for lamp bases, but brass at higher cost, china 30 ...

1050 aluminum mirror sheet is a typical grade of 1000 series aluminum mirror sheet. 1050 polished aluminum mirror sheet has a lot of performance, such as: 1.Super mirror surface, 95% reflectance. 2. The novel and unique material, and with high quality. 3. Scratch resistance, the surface hardness of diamond grade. 4. Environmental protection, non-toxic, fireproof, light weight. 5. Anti-interference, ...

5052 aluminum sheet is often referred to as ""Anodize Quality Aluminum"", as it has excellent finishing qualities and anodized coatings are bright and clear. The major alloying element in 5052 is magnesium in sufficient quantities to cause substantial lowering of the melting point without producing brittleness. When magnesium is used as the major alloying element, or in combination with manganese, the result is a ...

5005 h14 aluminum sheet commonly used in the manufacture of appliances, small boats, gas lines, refrigerator panels, and utensils. 5005 is also used in architectural components, and as an electrical conductor. Especially useful where excessive finishing costs are encountered in the use of 3003 alloys due to surface roughness upon drawing. 5005 Aluminum sheet is often used when the material will be anodized and ...

5083 aluminum sheet of Huawei Aluminum is belongs to the Al-Mg-Si alloy, the usage has a wide range, 5083 aluminum sheet plate is the most promising alloy. 5083 aluminum has good corrosion resistance, excellent weld-ability, good cold work-ability, and medium strength. The main alloy elements is magnesium, with good forming process-ability, so 5083 aluminum sheet usually used in the manufacture of aircraft fuel t ...

3003 aluminum sheet is a very cost effective grade, as it combines substantial strength and corrosion resistance, with an attractive finish. It is used for stamped and formed parts and can be finished with mechanical and organic finishes. 3003-H14 Aluminum Sheet Excellent weldability and formability, with good corrosion resistance makes 3003 Aluminum Sheet a popular and economical choice. 3003 Aluminum Sheet h ...