What is 5052 aluminum sheet/plate? 5052 alloy metal aluminum sheet plate belongs to 5000 series aluminum sheet, which is highly resistant to corrosion. It belongs It is an alloy that contains 0.25 percent chromium and 2.5 percent magnesium, and it belongs to 5 series. It’s widely used because of its formability and durability. It has high fatigue and medium static strength. It can be used in marine environments ...

Price list of aluminum plates for door Date:Based on January 5th,2022 SMM Price 2570.39USD Date LME LME Weekly Price 2022-12 LME Average 2022-12 SMM Average 2022-12-26(Monday) / 2358.33$ 2394.88$ 2721.60$ 2022-12-27(Tuesday) / 2022-12-28(Wednesday) 2343$ 2022-12-29(Thursday) 2371.5$ 2022-12-30(Friday) 2360.5$ Notes 1. Prices are updated at 10:00 am on weekd ...

1mm aluminum sheet product Aluminum sheet is a lightweight, corrosion-resistant, recyclable material. Due to its good electrical and thermal conductivity, it is widely used in construction, aviation, automobiles, packaging and other fields. Aluminum plates are also easy to process, easy to shape, and easy to cut. 1mm aluminum sheet weight per square meter An aluminum plate with a thickness of one millimete ...

There are fewer manufacturers producing 2000 series aluminum sheets in China. The quality is not yet comparable to that of foreign countries. At present, the imported aluminum plates are mainly provided by Korean and German producers. With the development of China's aerospace industry, 2000 series aluminum plate production technology will be further improved. 2000 series aluminum plate is characterized ...

Specifications of 6005 aluminum plate Alloy 6005 Aluminum Sheet Temper O, T4, T6, T651 Thickness(mm) 0.3-600 Width(mm) 500-2600 Length(mm) customized Typical products Car fuel tank, Traffic vehicles 6005 Aluminum Sheet Chemical Composition Elements Al Cr Cu Fe Mg Mn Si Ti Zn Others Content (max) 97.5 to 99.0% 0.1% 0.1% 0.35% 0.4 to 0.6% ...

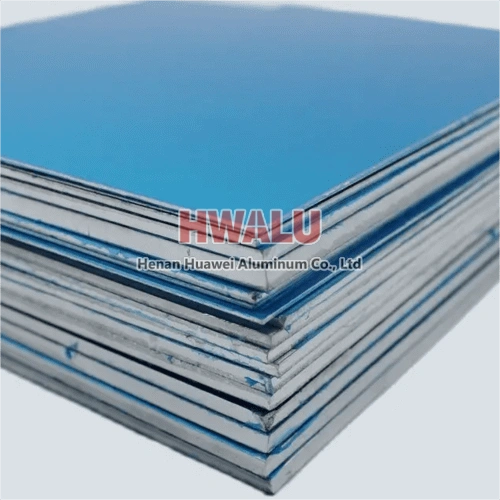

Aluminum sheet plate refers to aluminum material with width of 200mm over, and length of less 16000m. Custom Sizes 1 foot = 12 inch = 304.8 mm, 4 feet = 48 inches = 1220 mm Unit ( foot ): 4x4, 4x6, 4x8, 4x10, 4x12, 5x8, 6x8 etc Unit ( inch ): 12x12, 24x24, 24x36, 24x48, 36x36, 48x48 etc Hot sales sizes 4x8 foot aluminum sheet plate 5x8 ft ( 5 x 8 ), 60x96 inch ( 60 x 96 ), 1524 x 2438.4mm ...

The 1050 aluminum alloy is formed from pure aluminum by added a small amount of copper element, and the 1050 aluminum plate has low strength, excellent formability, surface treatment property, weldability and corrosion resistance. Besides, the industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the strength is low, it can ...

Aluminum 1100 sheet is a commercially pure aluminum. 1100 has excellent welding characteristics; it is also soft and ductile so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 is however non-heat treatable. As 1100 has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications wher ...

2024 T3 aluminum sheet has same characteristics as tubing, however, the sheet is alclad for corrosion resistance. Alclad is a metallurgically bonded aluminum or aluminum alloy coating that is anodic to the core, thus electrolytically protecting the core against corrosion. Tensile strength 70,000 psi, yield strength 50,000 psi. 5086 aluminum sheet is used for: boat hulls cabinets and panels equipment processing ...

The 5052 h34 aluminum sheet is highly resistant to corrosion. It is an alloy that contains 0.25 percent chromium and 2.5 percent magnesium. It’s widely used because of its formability and durability. It has high fatigue and medium static strength. It can be used in marine environments without worry of corrosion. This metal also has excellent thermal conductivity and low density, which is commonly found with other ...

Choosing trust worthy mirror aluminum sheet 3003 suppliers is the guarantee of choosing qualified mirror aluminum sheet product. There are a lot of problems to be aware of when buying mirrored aluminum sheet, if you donot pay attention to it in the process, it is easy to buy inferior products. Although there are many mirror aluminum sheet suppliers in the market, if you donot pay attention, people will miss th ...

3003 H14 Aluminum Sheet is alloyed with 1.2% maganese to provide a tensile strength range of 17 to 30 KSI. 3003 has Excellen workability, weldability, and corrosion resistance. 3003 Aluminum Alloy contains Manganese as its major alloying element. 3003 Aluminum is an alloy with very good corrosion resistance and moderate strength. It is not heat treatable and develops strengthening from cold working only. 3003 ...