what is 5005 aluminium sheet plate? 5005 alloy metal aluminium sheet plate belongs to 5000 series aluminum sheet . 5005 aluminium sheets can be cut to size at customers’ need. Mg is the principal element in the 5005 aluminium sheet and when it used as main alloying element or combined with Mn, high strength and no-heat treatable properties can be realized. 5005 aluminium sheet has many tempers available, such as ...

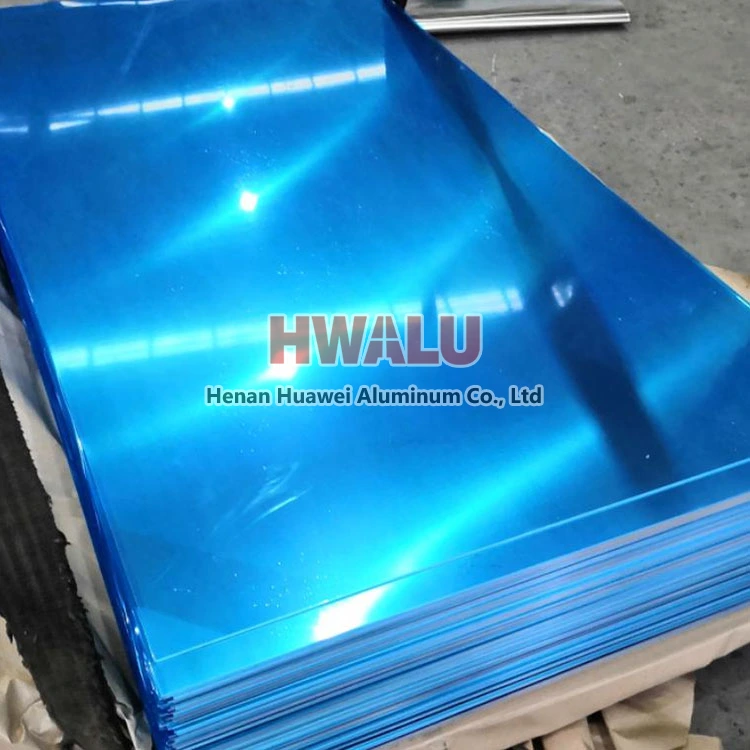

Where to buy anti-rust aluminum sheet? Take you to understand Antirust aluminum sheet Antirust aluminum sheet refers to an aluminum sheet containing a certain amount of manganese alloy and magnesium alloy. Among all the series of aluminum sheets, the three-series and five-series aluminum sheets are mainly called Antirust aluminum sheets, because a proper amount of manganese alloy and magnesium alloy is ad ...

Introduce you to 2014 aluminum sheet 2014 aluminum sheet alloy elements for the copper, known as hard molybdenum, with high strength and good cutting processing performance; 2014 aluminum sheet used in the requirements of high strength and hardness (including high temperature) of the occasion, also known as 2 military aluminum ; 2014 aluminum sheet application: heavy forgings, thick plates, and ex ...

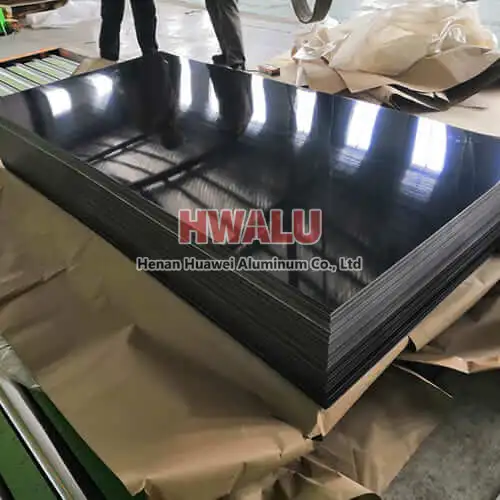

What is Black Aluminum Sheet Black aluminum sheet refers to an aluminum sheet that has a black effect after surface treatment. This type of aluminum sheet is processed through a series of surface treatment processes on the basis of the original aluminum material. It has a wide range of uses, including architectural decoration, furniture manufacturing, and home appliance panels. It can also be used as parts and c ...

Introduction to Aluminium 3 Bar Tread Plate At Huawei Aluminum, we pride ourselves on being a leading manufacturer and wholesaler of Aluminium 3 Bar Tread Plate, a versatile and durable product designed to cater to a wide range of industrial, commercial, and decorative applications. Our state-of-the-art manufacturing process ensures high-quality products that meet the global standards and specifications our clie ...

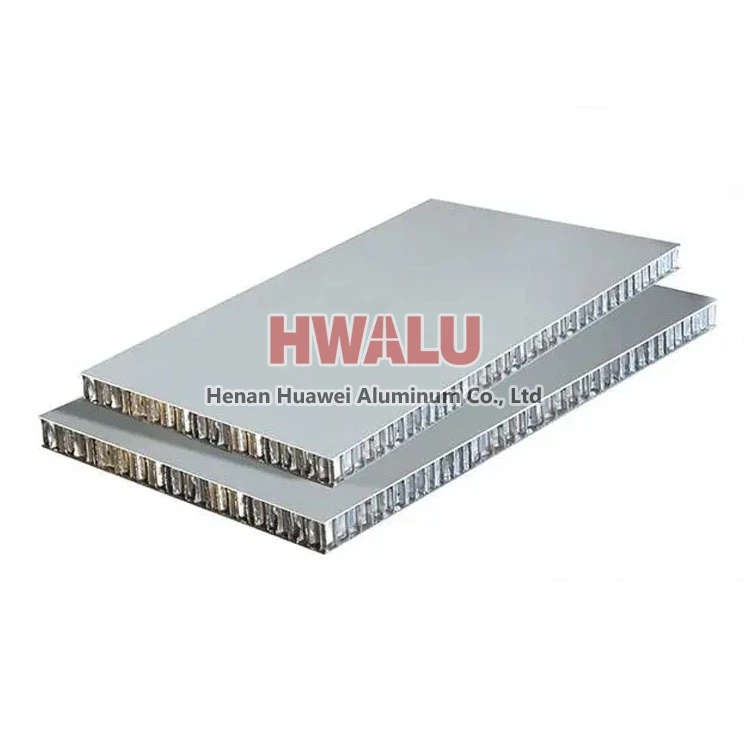

What is Honeycomb Aluminum Panel Honeycomb Aluminum Panel is an aluminum panel with a regular honeycomb structure, also known as honeycomb aluminum core panel or aluminum-plastic panel. It consists of two layers of metal outer plates and a middle honeycomb aluminum core layer. The middle honeycomb aluminum core layer is composed of many hexagonal honeycomb sections. These hexagonal honeycomb sections are connect ...

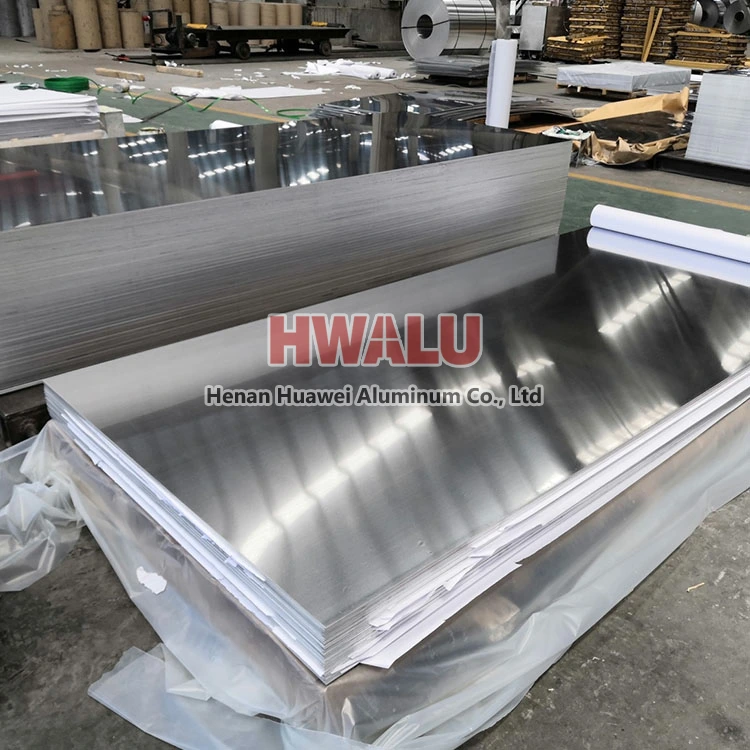

Aluminum is one of the metals most widely used in industry and daily life, when it comes to the aluminum alloy, the 1000 series aluminum sheet come to our mind, there are two typical aluminum sheet in 1000 series aluminum sheet alloy, they are 1050 aluminum sheet and 1060 aluminum sheet, they are all with high content of aluminum, they looks like the same, but their types are different, what is the difference bet ...

The first four digits "6061" represent the grade. The "T6" at the back represents the processing state, which generally has 2-3 digits and numbers, and there are five common aluminum alloy processing states. The first digit indicates the alloy element, "6" refers to the 6-series aluminum-magnesium-silicon alloy. The second digit indicates the number of reshaping, "0" refers to the original alloy, no special ...

Insulation aluminum plates are commonly used in daily life. Mainly used to manufacture thermal insulation equipment. The material is thermal insulation aluminum plate, which not only has the thermal insulation effect, but also is not easy to be damaged and has a long service life. Therefore, the actual value of the thermal insulation aluminum plate is very high. However, there are many insulating aluminum panels ...

7075-T6 aluminum is 7075 aluminum in the T6 temper. To achieve this temper, the metal is solution heat-treated and artificially aged until it meets standard mechanical property requirements. The graph bars on the material properties cards below compare 7075-T6 aluminum to: 7000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the re ...

Aluminium Alloy 5754 H111 Sheets has excellent corrosion resistance especially to seawater and industrially polluted atmospheres. It has higher strength and is typically used in ship building, vehicle bodies, fishing equipments. It displays excellent weldability and average machinability. Henan huawei aluminum supplies an unrivalled quality of Aluminum Alloy 5754 H111 sheets, that are durable and serve their purp ...