Alloy properties of 5000 series aluminum sheets The 5000 aluminum plate series is a commonly used alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as an aluminum-magnesium alloy. Its main features are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloys in the same area is lower than other series, so it i ...

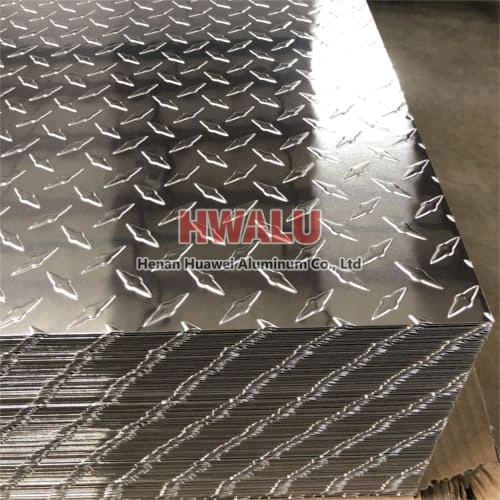

What is aluminum checker plate? Aluminum checker plate, also known as pattern aluminum plate or diamond aluminum plate, is an aluminum plate with a raised diamond pattern on one side. Aluminum checker sheet's unique pattern of raised diamonds or lines provides excellent anti-slip properties, making it ideal for applications where slip resistance is important. Aluminum checker plate thickness The applicatio ...

Introduction Huawei Aluminum, a leading manufacturer and wholesaler in the aluminum industry, is proud to present our 1/4 Aluminum Checker Plate. These plates are designed for enhanced slip resistance and aesthetic appeal, making them a popular choice for a variety of applications, from flooring in industrial and commercial settings to decorative accents in architectural design. With a commitment to quality and ...

Introduction of Aluminum Sheet Plates for Heat Sinks At Huawei Aluminum, we specialize in manufacturing high-quality aluminum sheet plates designed for optimal heat dissipation. Our products are engineered to meet the rigorous demands of modern electronic devices, ensuring efficient thermal management and enhanced performance. Why Choose Aluminum for Heat Sinks? Aluminum is the material of choice for heat sink ...

What are the characteristics of 4017 aluminum plate? 4017 aluminum sheet plate has a variety of thicknesses and pattern sizes. 4017 aluminum alloy is a shiny surface similar to 3003. 4017 aluminum alloy provides durability. The constructed aging isotherm shows that EN 4017 with 0.19% Mg reaches a lower peak intensity than EN 4017 material with 0.43% Mg. The higher Mg variant of EN 4017 is comparable to the ag ...

what is Aluminum corrugated sheet? Aluminum corrugated sheet is a new type of aluminum sheet roofing material, which is cold-formed into various wave types after rolling. With the rapid development of the economy, corrugated aluminum sheets also enter large-scale public buildings from industrial buildings Aluminum roofing sheets are waved pure aluminum sheets or alloy aluminum plates and rolled waves of cold- ...

Grade 1050 aluminum sheet for making composite panel: An unalloyed non heat-treatable aluminium that is easily worked and has high resistance to corrosion and low strength.Aluminum sheet comes in 6061-T6 and 3003-H14 alloys. The 6061-T6 is the harder, more machinable aluminum sheet. The 3003-H14 is a softer, more formable aluminum sheet (when drilled and tapped, it is like chewing gum). Grade 5083 marine alumi ...

6063-T5 aluminum is 6063 aluminum in the T5 temper. To achieve this temper, the metal is artificially aged until it meets standard mechanical property requirements. The graph bars on the material properties cards below compare 6063-T5 aluminum to: 6000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relevant set. A half-full ba ...

3004 aluminum sheet belongs to AL-Mn series alloys and are the most widely used rust-proof aluminum. 3004 aluminum sheet has good forming, welding and corrosion resistance, excellent shape processing characteristics, good conductivity, smooth surface, good plasticity and pressure resistance, higher strength than 3003 aluminum sheet. The thickness of aluminum sheet 3004 is 0.2-4.5mm, the width is 100-2600mm, th ...

1. Changes in daily aluminum plate prices As the basic raw material of aluminum plate, the price fluctuation of aluminum ingot directly affects the price of aluminum plate. 2. Surface spraying process of aluminum plate Common surface treatment processes for aluminum plate manufacturers include: fluorocarbon paint spraying, polyester paint spraying, thermal transfer wood grain, imitation stone grain spray ...

3004-H32 aluminum is 3004 aluminum in the H32 temper. To achieve this temper, the metal is strain hardened, and then stabilized, to a strength that is roughly a quarter of the way between annealed (O) and full-hard (H38). It has the second highest ductility compared to the other variants of 3004 aluminum. The graph bars on the material properties cards below compare 3004-H32 aluminum to: 3000-series alloys (top), ...

Aluminum plate 5083, Marine aluminum plate is a new field of research and application of aluminum plate products. At present, the production capacity of Marine aluminum plate has become an important index to measure the comprehensive strength of aluminum plate production enterprises. Then why 5083 aluminum plate will be favored by shipping companies? The magnesium alloy in Huawei 5083 aluminum plate has hig ...