what is 3003 aluminum sheet? 3003 alloy metal aluminum sheet plate is approximately 20% stronger than 1100 series aluminium. 3003 alloy is readily formed by either conventional cold working or hot working. We offer high-quality 3003 flat aluminum sheet plate and tread plate covered by the ISO standard 6361 and the ASTM standards B209, B210, B211, B221, B483, B491, and B547. The 3003-H14 is a softer, more formabl ...

What is 18 gauge aluminum sheet? 18 gauge is a way of expressing the thickness of aluminum sheet, which is typically about 0.0403 inches (or about 1.02 mm) thick. This is a common specification for a variety of aluminum applications, including automotive panels, signage and lightweight structural components. 18 gauge aluminum sheet equivalent expression 18 ga aluminum sheet 18 gauge aluminium sheet ...

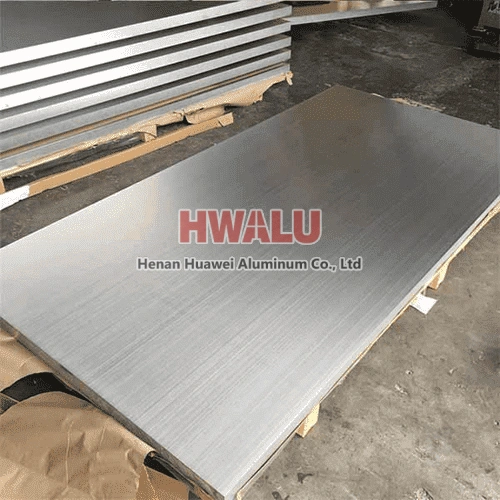

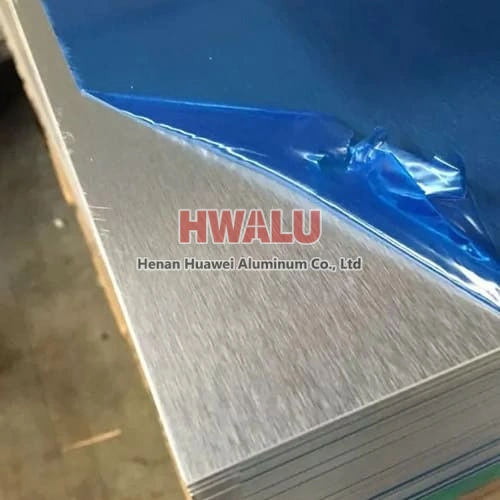

What is brushed aluminum sheets Brushed aluminum sheets are aluminum sheets that have a brushed finish applied to them. This finish is achieved by mechanically brushing the surface of the aluminum with a fine abrasive material. The brushing process creates a distinctive pattern of fine lines on the surface, giving the aluminum a stylish, modern look. Brushed aluminum sheets are commonly used in interior a ...

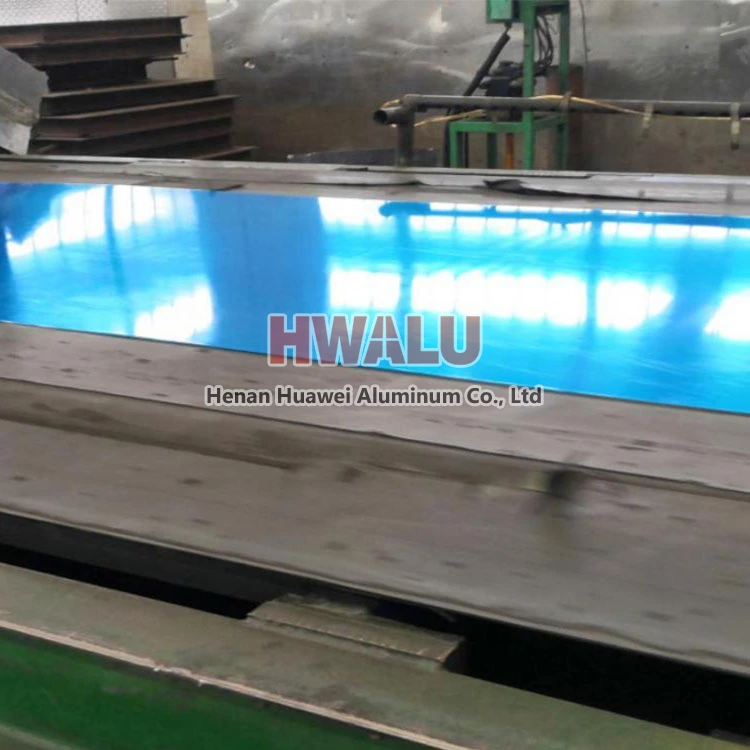

what is 1 4 aluminum plate? 1 4 aluminum plate means the thickness of the aluminum plate is 1/4 inch 1/4 inch in millimeters is: 1 inch = 25.4 mm 1/4 inch = 6.35mm 1 4 aluminum plate The aluminum plate is divided into: (unit mm) according to the thickness Sheet (aluminum sheet): 0.15-2.0 Conventional sheet (aluminum sheet): 2.0-6.0 Medium plate (aluminum plate): 6.0-25.0 Thick plate (alu ...

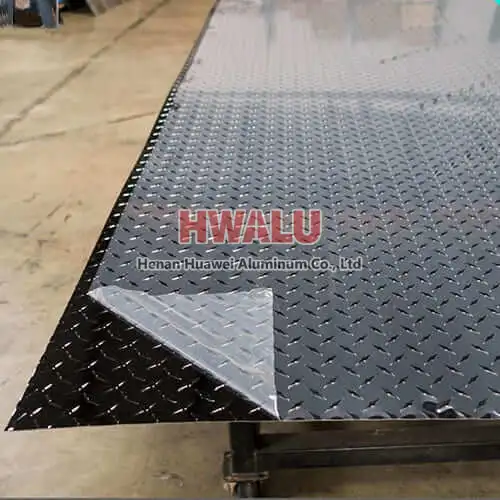

What is black aluminum checker plate Black aluminum checker plate, also known as black aluminum tread plate or black aluminum diamond plate, is an aluminum sheet with a raised diamond pattern on one side. This pattern provides slip resistance and is commonly used in various applications where traction and durability are required, such as truck beds, trailers, stairs, ramps, and industrial settings. The black ...

5454 Alloy Metal Aluminum Sheet Plate Features Al 5454 is non-heat-treatable aluminum and magnesium alloy. It is a medium-strength alloy that can be hardened (strengthened) by cold work; It is commonly used to manufacture welded structures, pressure vessels, and Marine services. The machining performance of Al 5454 is not satisfactory. It is best to use H-34 temper alloy processing. Oil-based lubricants a ...

Aluminum Gauge Chart Gauge Number Inches MM 7 0.1443 3.665 8 0.1285 3.264 9 0.1144 2.906 10 0.1019 2.588 11 0.09074 2.305 12 0.08081 2.053 14 0.06408 1.628 16 0.05082 1.291 18 0.04030 1.024 20 0.03196 0.812 22 0.02535 0.644 24 0.02010 0.511 26 0.01594 0.405 28 0.01264 0.321 30 0.01003 0.255

Aluminum is an extremely popular choice for sheet metal suppliers due to its cost effectiveness, flexible nature, and range of options and grades. For example, high strength aluminum can be specialized for the aerospace industry, while corrosion resistant aluminum alloys are ideal for marine applications. It is highly weldable, machinable, and weather resistant. Common grades of aluminum include: Grade 1100-H14 — ...

Both 7075-T6 aluminum and 7075-T7 aluminum are variants of the same material. They share alloy composition and many physical properties, but develop different mechanical properties as a result of different processing. There are 31 material properties with values for both materials. Properties with values for just one material (1, in this case) are not shown. 7075 aluminum sheet is one of the highest strength a ...

1. Cut corners With the continuous improvement of the national quality control system, the phenomenon of cutting corners is not as rampant as before. However, in order to reduce production costs, there are still some companies who take risks by cutting corners and using molds of substandard quality in the process of producing aluminum veneer products. , Resulting in unqualified wall thickness of the aluminum p ...

5005 Aluminum sheet is a lean aluminum magnesium alloy with low density and excellent thermal conductivity. This medium strength non-heat-treatable alloy is known for its corrosion resistance in alkaline marine situations. 5005 Aluminum sheet is readily machinable, and can be welded using TIG and MIG methods. It is important to note that anodizing is a critical part to how Aluminum 5005 is used. 5052-H32 Alumi ...

Aluminum 6061 T4 Sheet is solution heat treated and naturally aged giving it slightly lower tolerance accuracy than Aluminum 6061 T6, which undergoes artificial aging. T4 is also slightly less expensive than T6 and has a slightly lower ultimate tensile strength and yield strength, with a higher elongation percentage, which increases the formability of the T4 temper. Aluminum sheet 6061 T4 is also cost friendlier ...