what is 3003 aluminum sheet? 3003 alloy metal aluminum sheet plate is approximately 20% stronger than 1100 series aluminium. 3003 alloy is readily formed by either conventional cold working or hot working. We offer high-quality 3003 flat aluminum sheet plate and tread plate covered by the ISO standard 6361 and the ASTM standards B209, B210, B211, B221, B483, B491, and B547. The 3003-H14 is a softer, more formabl ...

what is 3105 aluminum sheet? 3105 aluminum plate belongs to a series of Al-Mn alloy, good rust resistance, good electrical conductivity, including 98% aluminum content, because the addition of 0.3% copper content, electrical conductivity is 41%; 3105 aluminum plate can not be heat treatment and reinforcement, so the use of cold treatment to improve its mechanical properties: annealing state plasticity is high, s ...

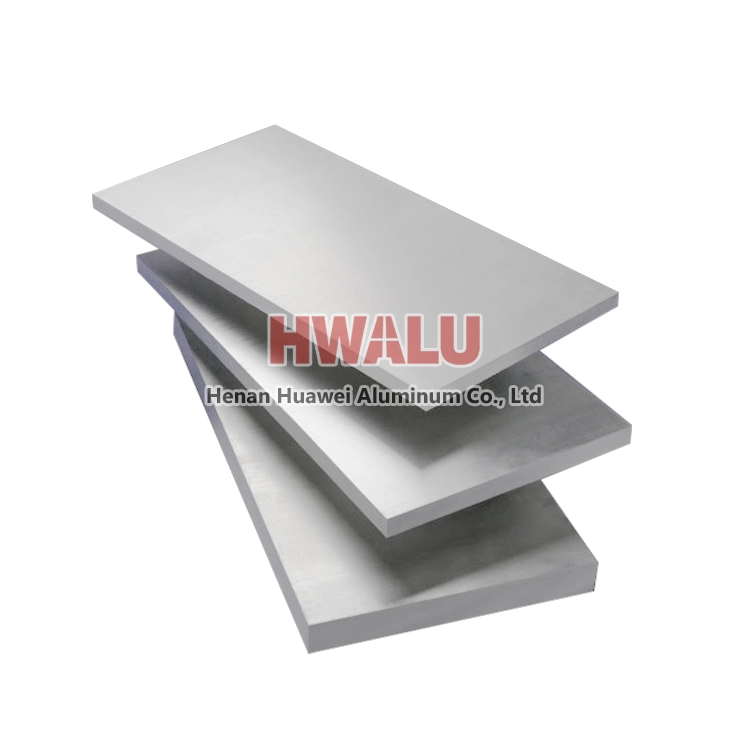

Medium thickess aluminum plate refers to aluminium plates with thick between 25mm ~ 200mm. Unit ( mm ): 25mm, 25.4mm, 26mm, 27mm, 28mm, 29mm, 30mm, 35mm, 40mm, 45mm, 50mm, 50.8mm, 100mm etc Unit ( cm ): 10 cm etc Unit ( inch ): 1, 2 etc

what is 1070 aluminum sheet? 1070 aluminum sheet has some features such as high plasticity, anti-corrosion, electrical conductivity and good thermal conductivity, but low strength. And the machinability is not good without heat treatment. It can be used for gas welding. This specific properties of 1070 aluminum alloy can be used to produce some structures such as aluminium gasket and capacitor, electronic wire ...

what is 1 4 aluminum plate? 1 4 aluminum plate means the thickness of the aluminum plate is 1/4 inch 1/4 inch in millimeters is: 1 inch = 25.4 mm 1/4 inch = 6.35mm 1 4 aluminum plate The aluminum plate is divided into: (unit mm) according to the thickness Sheet (aluminum sheet): 0.15-2.0 Conventional sheet (aluminum sheet): 2.0-6.0 Medium plate (aluminum plate): 6.0-25.0 Thick plate (alu ...

what is 2024 Alloy Metal Aluminum Sheet Plate? 2024 aluminum alloy is a high-strength aluminum alloy commonly used in the aerospace industry, as well as in other applications requiring a combination of high strength and good machinability. The alloy typically includes a small amount of copper as well as magnesium and is known for its excellent fatigue resistance. 2024 aluminum sheet and plate are available in ...

What is perforated aluminum sheet? Perforated aluminum sheet is punched on the aluminum plate with professional CNC equipment on a variety of perforated aluminum sheets, called perforated aluminum sheets After punching all kinds of holes through bending machine edge pressing, appearance to do fluorocarbon, or powder spraying, do not let the aluminum plate natural oxidation, or for beauty, do a variety of favori ...

Among the tempers from O to H32, the most common temper of the 1100 aluminum sheet is h14, we called it aluminum sheet 1100 h14. The H temper is hard representation, H is followed by 2-3 digits, indicating the subdivision temper of the H. Take 1100 aluminum sheet as the example, the first digit indicates the processing status of the 1100 aluminum sheet: H1: Work hardened temper, indicating that the aluminum ...

3105-H24 aluminum is 3105 aluminum in the H24 temper. To achieve this temper, the metal is strain hardened to a strength that is roughly halfway between annealed (O) and full-hard (H18). The graph bars on the material properties cards below compare 3105-H14 aluminum to: 3000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relev ...

5052 aluminum sheet are various auto parts, sheet metal parts, mechanical parts, automobiles, aircraft fuel tanks, warships, submarines, containers, household appliance use, refrigerator liners and so on. Performance of 5052 aluminum sheet: Tensile strength (σb): 170~305MPa, Yield strength (σb): 0.2 (MPa), Elastic modulus (E): 69.3~70.7Gpa, Annealing temperature: 345°C. 6061 aluminum sheet alloy is strong, e ...

Both 5052 aluminum and 5005 aluminum are aluminum alloys. They have a very high 98% of their average alloy composition in common. For each property being compared, the top bar is 5052 aluminum and the bottom bar is 5005 aluminum. Mechanical Properties Brinell Hardness 46 to 83 28 to 64 Elastic (Young's, Tensile) Modulus, GPa 68 68 Elongation at Brea ...

1050 aluminium alloy is an aluminium-based alloy in the "commercially pure" wrought family (1000 or 1xxx series). As a wrought alloy, it is not used in castings. Instead, it is usually formed by extrusion or rolling. It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1050 alloy is also sometimes used for the manu ...