Thin aluminum sheet refers to aluminium sheets with thick between 0.15mm ~ 2mm. The parameters of 5052 thin aluminum plate as an example are for reference only. If you want to know more about the thin aluminum plate, please contact us as soon as possible. Alloy State Thickness Width Tensile strength (Mpa) Elongation (δ%)(Scaling distance 50) 5052 0 >0.5~1.3 >1.3~4.5 Above 500mm ...

Take you to know 6061 aluminum sheet/plate 6061 alloy metal aluminum sheet plate belongs to 6000 series aluminum alloy sheet, The main alloying elements are magnesium and silicon and form Mg2Si. It is a high-quality alloy product produced by heat treatment and pre-stretching. Although its strength cannot be compared with 2000 series alloy or 7000 alloy series, the composition of 6061 aluminum alloy is mainly Mg ...

3005 Aluminum sheet overview 3005 alloy metal aluminum sheet plate belons to aluminium sheet 3xxx series. The strength of 3005 al-mg aluminum plate is about 20% higher than that of 3003 aluminum plate, and corrosion resistance is also better.Also known as anti-rust aluminum plate. 3 series aluminum plate is mainly composed of manganese, with the content between 1.0 and 1.5.It is a series with better anti-rust ...

what is 3105 aluminum sheet? 3105 aluminum plate belongs to a series of Al-Mn alloy, good rust resistance, good electrical conductivity, including 98% aluminum content, because the addition of 0.3% copper content, electrical conductivity is 41%; 3105 aluminum plate can not be heat treatment and reinforcement, so the use of cold treatment to improve its mechanical properties: annealing state plasticity is high, s ...

Welcome to Huawei Aluminum, your premier destination for high-quality '032 aluminum sheet' products. Our dedication to excellence in manufacturing and supplying aluminum sheets has made us a leading name in the industry. The '032 aluminum sheet' is versatile, durable, and widely used across various industries, including automotive, construction, aerospace, and more. About '032 Aluminum Sheet' The '032 aluminum ...

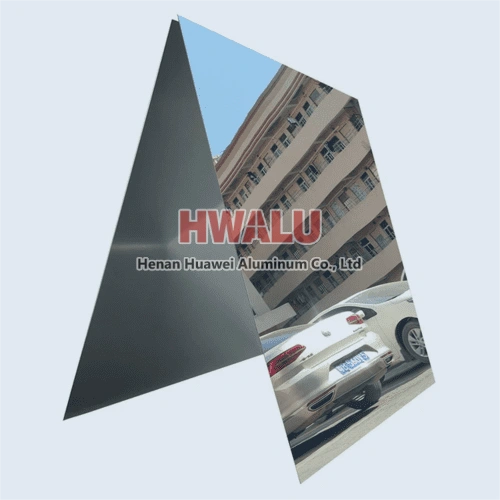

What is reflective aluminum sheet? Reflective aluminum plate is a type of aluminum plate with a reflective surface that can reflect light and heat. Its surface is polished or coated to form a special structure with reflective function. When light irradiates the surface of the aluminum plate, reflection occurs. Because aluminum has good electrical conductivity, it can quickly conduct the light to the inside of th ...

063 Aluminum Sheet introduction The ‘063 Aluminum Sheet’ refers to an aluminum sheet with a thickness of 0.063 inches, which is approximately 1.60mm. This type of sheet is known for its versatility and is commonly used in various applications due to its favorable properties such as corrosion resistance, good machinability, high strength after heat treatment, light weight, good weldability, and the ability to be ...

6063-T5 aluminum is 6063 aluminum in the T5 temper. To achieve this temper, the metal is artificially aged until it meets standard mechanical property requirements. The graph bars on the material properties cards below compare 6063-T5 aluminum to: 6000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relevant set. A half-full ba ...

Alloy 2024 T3 Aluminum Sheet is a high-strength, corrosion-resistant aluminum alloy material commonly used in the manufacture of the aerospace industry, automobile manufacturing, shipbuilding, and other applications that require lightweight, high-strength materials. Among them, "2024" means that the main components of the alloy are aluminum, copper and magnesium, and T3 means that the material has undergone a ...

Aluminum 1100 sheet is a commercially pure aluminum. 1100 has excellent welding characteristics; it is also soft and ductile so is ideal for applications that require intricate forming as it work hardens slower than other alloys. 1100 is however non-heat treatable. As 1100 has excellent resistance to corrosion it is widely used in the chemical and food processing industries also for giftware and applications wher ...

3004 aluminium alloy sheet is the most widely used antirust AL-Mn aluminium alloy.The forming, solderability, corrosion resistance of 3004 aluminium sheet is good. For the processing of parts that require good formability, high corrosion resistance and good solderability, or require both these properties and require higher strength than 1XXX aluminum alloy work, such as kitchen utensils, food and chemical process ...

Aluminum 1060 is the most common used grade in 1000 series aluminum. The aluminum content of 1060 aluminum alloy is more than 99.6%, so it is also known as pure aluminum alloy. 1000 series aluminum alloy is a common series in the aluminum alloy. The advantages of 1000 series are the most commonly used series, the production process is relatively single, the technology is relatively mature, the price has a grea ...