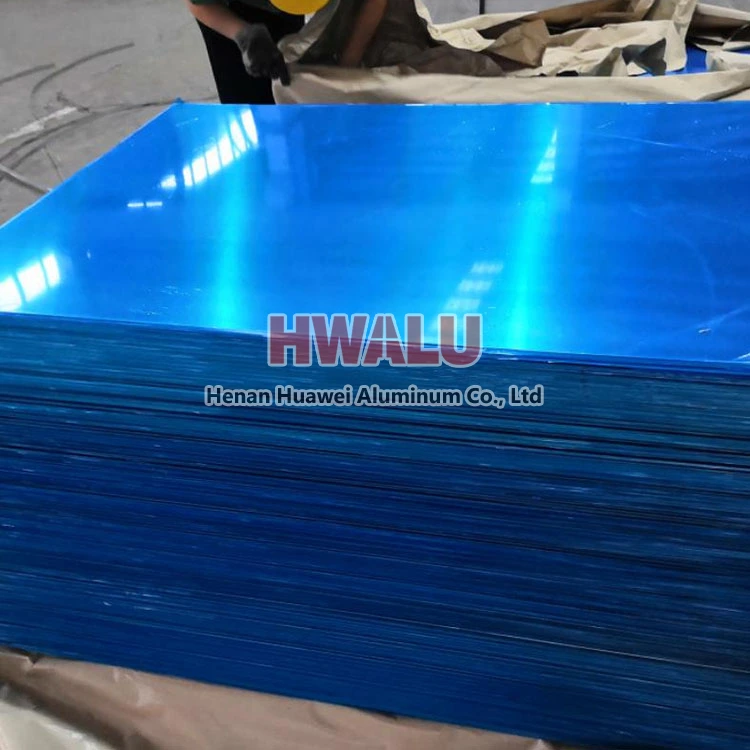

What is the cold rolling aluminium sheet? Cold rolling of aluminum sheets is usually carried out on a four-high or six-high mill. The cold rolling process of aluminum sheets is generally divided into rough rolling, intermediate rolling, and finishing rolling. Rough rolling and intermediate rolling focus on increasing pressure, strengthening the production process, and shortening the production cycle. The visc ...

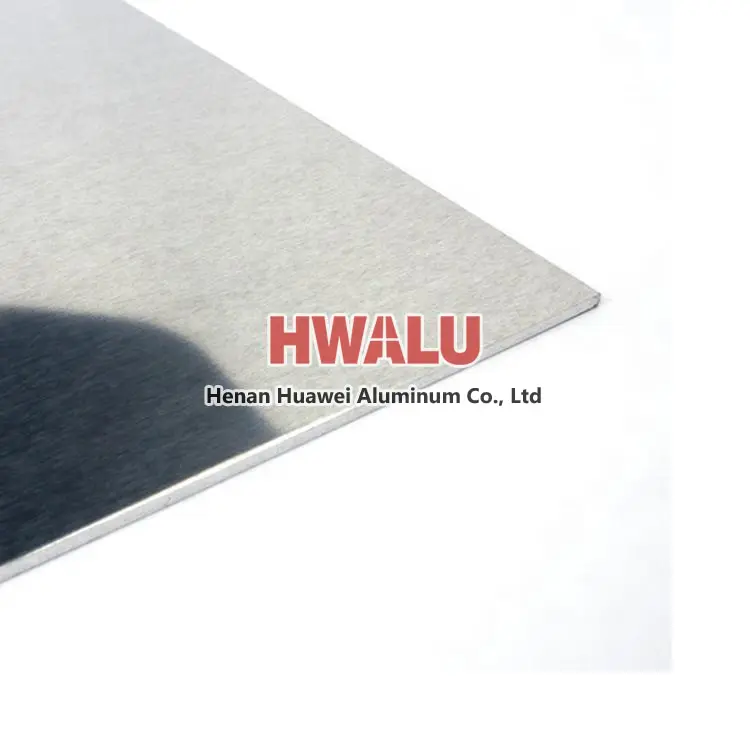

Aluminum sheet plate refers to aluminum material with a thickness of 0.2mm over to less 500mm. Classification by thickness Thin aluminum sheet plate Standard thickness aluminum sheet plate Medium thickness aluminum plate Thick aluminum sheet plate Super thick aluminum sheet plate Different thickness aluminum sheet determines its different functions. And different functions can be used in diff ...

What is embossed aluminum sheet plate? What is embossed aluminum? Embossed aluminum plate, also known as aluminum embossed plate, is an aluminum product that is formed on the surface with various patterns on the surface through rolling processing based on the aluminum plate. Embossed aluminum sheet not only has the basic characteristics of aluminum sheets, such as light weight, corrosion resistance, easy process ...

Introduction of Aluminum Sheet Plates for Heat Sinks At Huawei Aluminum, we specialize in manufacturing high-quality aluminum sheet plates designed for optimal heat dissipation. Our products are engineered to meet the rigorous demands of modern electronic devices, ensuring efficient thermal management and enhanced performance. Why Choose Aluminum for Heat Sinks? Aluminum is the material of choice for heat sink ...

What is the cold rolling aluminium sheet? Cold rolling of aluminum sheets is usually carried out on a four-high or six-high mill. The cold rolling process of aluminum sheets is generally divided into rough rolling, intermediate rolling, and finishing rolling. Rough rolling and intermediate rolling focus on increasing pressure, strengthening the production process, and shortening the production cycle. The visc ...

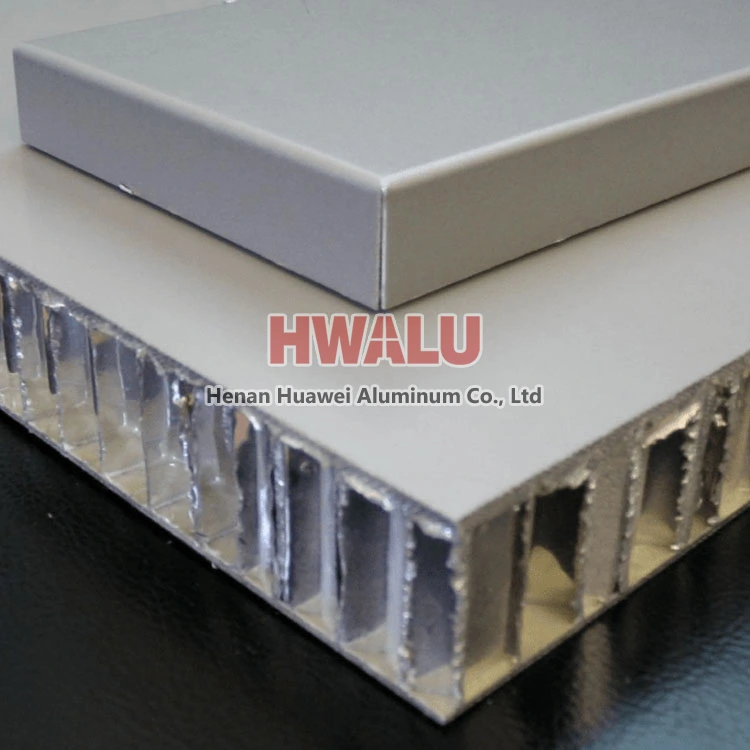

What is aluminum composite panel? Aluminum composite panel is a composite material made of aluminum and aluminum, such as: a honeycomb aluminum panel made of aluminum substrate and aluminum honeycomb core, which is a type of acm panels. Easy to process Aluminum composite panels can be machined using common woodworking or metalworking tools without special tools. It can be easily cut, slotted, punched, drilled, ...

Material Notes: Same nominal composition but higher Si and Fe impurity limits than Al-5657 Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR DESIGN. Composition Notes: Composition information provided by the Aluminum Association and is not for design. Key Words: UNS A95005; ISO AlMg1; Aluminium 5005-H34; AA5005-H34; Al5005-H34 5005 h34 aluminum sheet Availabl ...

The cost of hot rolling is higher than that of cast rolling. However, the difference between them is not just a matter of production cost. The maturity level of hot rolling technology and equipment control level are far higher than those of cast-rolled products. Moreover, hot rolling is rolled within the recrystallization temperature range of aluminum alloy without alloy composition. Restriction, which means that ...

The aluminum content of 1050 aluminum sheet can reach 99.5%, so the 1050 aluminum sheet is also called pure aluminum sheet. It belongs to the common product. The advantage of 1050 aluminum sheet is having mature technology, and the price with other aluminum alloy has a great advantage. The common state of 1050 aluminum sheet is divided into O, H12, H14, H16, H18, H112, H22, H24, H26, H28, H38, H36, H32 and so ...

The aircraft industry is regard as the most advanced industry, and the requirements on the aircraft part is very strict. The 7075 and 7005 are the most common use aluminum alloy in aluminium sheets for aircraft. Today our topic is 7075 aluminium sheet, 7075 is an aluminum alloy with zinc as the main alloying element, but sometimes a small amount of magnesium and copper are added. Among them, super-hard aluminu ...

The applications of automotive aluminum sheet increased significantly The latest research shows that the future demand for aluminum sheets will grow at an unprecedented rate. 2014 and 2015 are considered a turning point in the automotive industry from traditional steel to aluminum and other lightweight materials, including the use of aluminum instead of advanced high strength steel (AHSS). I ...