what is 6082 aluminum sheet? 6082 aluminum sheet heat treatment can strengthen the alloy, with good formability, weldability, machinability and corrosion resistance, while a moderate strength, after annealing can still maintain good operability, mainly for mechanical structure Including bar, sheet, pipe and profile. 6082 and 6061 aluminum plate are both Al-Mg-Si aluminum alloy which can be strengthened by agi ...

What is reflective aluminum sheet for lighting Reflective aluminum sheets for lighting are typically made from high-quality aluminum with a highly reflective surface. These sheets are designed to reflect light efficiently, making them ideal for various lighting applications. In lighting, reflective aluminum sheets are commonly used in fixtures and reflectors to direct and enhance the light output. The reflect ...

4x8 aluminum checker plate product The 4x8 aluminum checker plate is a popular type of metal plate that features a raised pattern on the surface of the aluminum plate. Aluminum pattern plates not only retain the excellent characteristics of ordinary aluminum alloy materials, such as excellent corrosion resistance and weather resistance, but also have some special properties, such as anti-skid, wear-resistant, an ...

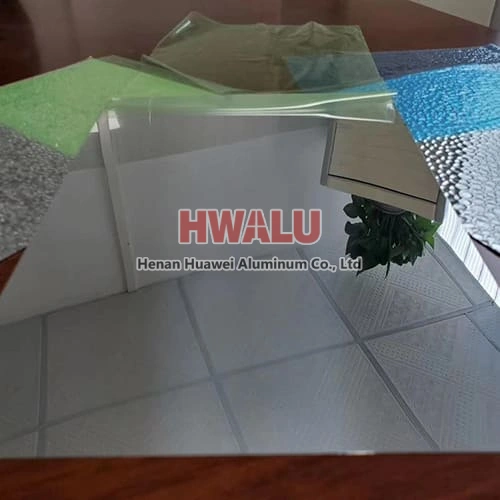

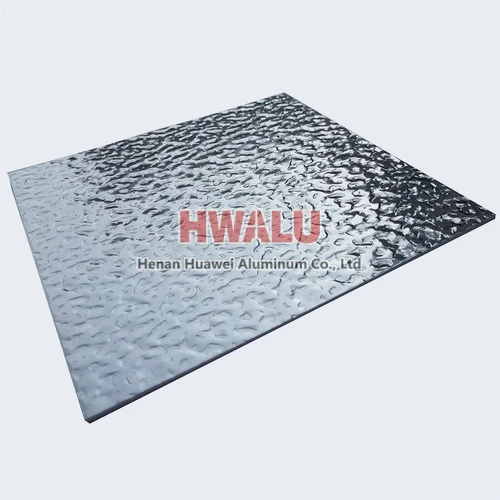

What is embossed aluminum sheet plate? What is embossed aluminum? Embossed aluminum plate, also known as aluminum embossed plate, is an aluminum product that is formed on the surface with various patterns on the surface through rolling processing based on the aluminum plate. Embossed aluminum sheet not only has the basic characteristics of aluminum sheets, such as light weight, corrosion resistance, easy process ...

Understanding 0.25 Inch aluminum sheets 0.25 inch aluminum sheet, also known as a quarter-inch aluminum sheet, is a standard thickness for aluminum plates. 0.25 inch aluminum sheet is also called 1/4 inch aluminum sheet, converted to mm is 6.35mm, which is a medium-thick plate. The importance of choosing the right thickness Choosing the right thickness for an aluminum sheet, or any material, is crucial ...

Aluminum alloys have strong corrosion resistance. They are sensitive to high temperatures ranging between 200 and 250°C (392 and 482°F) and might lose some of their strength. However, the strength of the aluminium alloys can be increased at subzero temperatures, making them ideal low-temperature alloys. We can produce many alloys by customer's requirements. It mainly includes 1xxx, 2xxx, 3xxx, 4xxx, 5xxx, ...

5083 marine Aluminum Alloy sheet in good corrosion resistance, the corrosion rate in seawater is very slow, the uniform corrosion rate is generally 0.025-0.05mm/ years, can resist the corrosion of seawater and marine atmosphere on the ship, reduce oil and maintenance cost, long service life. 5083 marine Aluminum Alloy plate with high strength and low fracture toughness, it is suitable for hull structure material, ...

We offer a great selection of aircraft aluminium sheet in a variety of specifications. The mechanical properties of an alloy are an important factor in the decision where to use it during construction.Look through our extensive assortment of aircraft aluminum sheet here .With its good strength to weight and cost ratio, aluminum is still used very widely in the industry,Aluminum sheets become to be the king in air ...

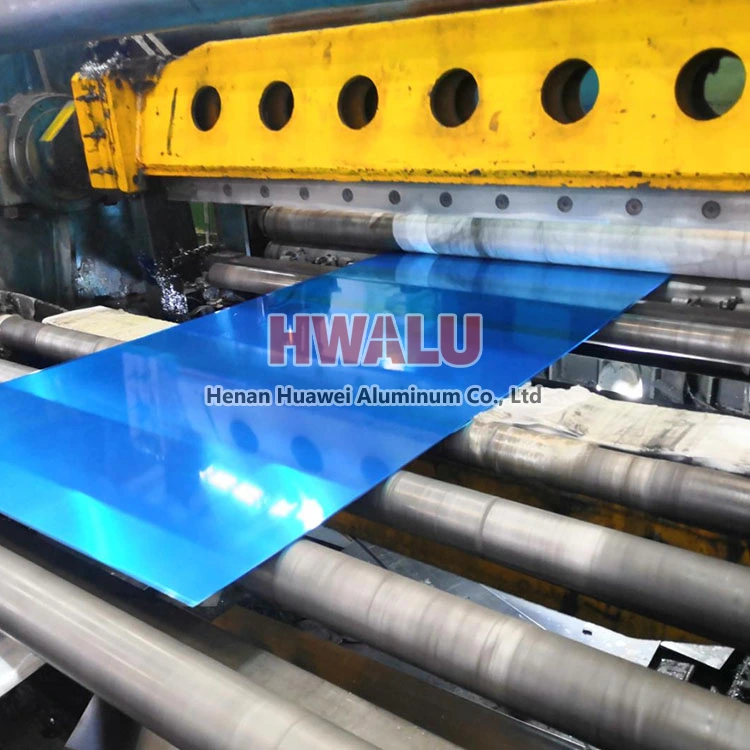

First, the pure aluminum ingots are added to the aluminum alloy melting furnace to melt. These aluminum ingots that become blanks are removed from impurities such as dezincification, titanium and silicon. In this 25 tons of aluminum melting furnace, 24 tons of aluminum can be melted at a time, which requires 3 to For 8 hours, the furnace temperature is 750°C, and the melting point of aluminum is 660°C. During the ...

Aluminium Alloy 5754 H111 Sheets has excellent corrosion resistance especially to seawater and industrially polluted atmospheres. It has higher strength and is typically used in ship building, vehicle bodies, fishing equipments. It displays excellent weldability and average machinability. Henan huawei aluminum supplies an unrivalled quality of Aluminum Alloy 5754 H111 sheets, that are durable and serve their purp ...

2024 aluminium alloy sheet is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has average machinability. Due to poor corrosion resistance, it is often clad with aluminium or Al-1Zn for protection, although this may reduce the fatigue strength. ...

3004-O aluminum is 3004 aluminum in the O temper. To achieve this temper, the metal is strain hardened, and then stabilized, to a strength that is roughly a quarter of the way between annealed (O) and full-hard (H38). It has the second highest ductility compared to the other variants of 3004 aluminum. The graph bars on the material properties cards below compare 3004-H32 aluminum to: 3000-series alloys (top), all ...