what is Aluminum corrugated sheet?

Aluminum corrugated sheet is a new type of aluminum sheet roofing material, which is cold-formed into various wave types after rolling. With the rapid development of the economy, corrugated aluminum sheets also enter large-scale public buildings from industrial buildings

Aluminum roofing sheets are waved pure aluminum sheets or alloy aluminum plates and rolled waves of cold-formed into a variety of pressure plates.

Aluminum deep corrugated panels can be fabricated on two nominal corrugated profiles, exposed or painted surfaces, and finished on smooth or stucco relief surfaces. The strength and stiffness of corrugated profiles are superior to standard aluminum jackets. A deep corrugated aluminum plate is an important protective outer surface of a mechanical insulation system. In flat, large equipment, towers, containers, and vertical cylindrical containers, the outer diameter is greater than 8 feet. Deep corrugated aluminum plates help protect the insulation layer and underside from physical damage, UV exposure, corrosive environments, and water.

The advantages and characteristics of Aluminium /Roofing sheets

Lightweight, custom sizes, rust-proof, heat resistant, high strength, color-rich, convenient construction, anti-earthquake, fireproof, rainproofing ( waterproof ), long life, maintenance-free characteristics, rust-proof etc

- Aluminium Corrugated/Roofing sheets are very light, with high strength weight ratio.

- Aluminum is increasingly popular in facilities and buildings. It can resist corrosion in almost any environment. Even in highly corrosive industrial environments, it resists fumes and vapors from organic compounds, as well as ammonia, carbon dioxide, and other chemicals and acids (such as hydrochloric, nitric, and sulfuric). This corrosion resistance gives the metal a long service life and a good appearance throughout its life.

- The luster and brightness of aluminum enliven the surroundings. Because it doesn’t dye, it retains its brightness and luster for a long time. Aluminum corrugated boards can carry out a variety of surface treatments. Color and texture, protect them and further improve their appearance.

- The aluminum structure can be easily disassembled, transported, and reassembled in a new location. Easy maintenance and cleaning.

Parameters

Alloy: 3003, 5052, 5154, 5454, 6063 etc

Thickness: 0.35mm, 0.4mm, 0.5 mm, 0.7 mm gauge, 2mm, 4.0mm, 0.55gauge etc

Surface Treatment: color coated, diamond embossed, oven prepainted etc

Color: Blue, orange, stone, green etc

Type: Curve wave, tile, step tiles, wide gutter etc

Dimensions of corrugated aluminum roofing plate

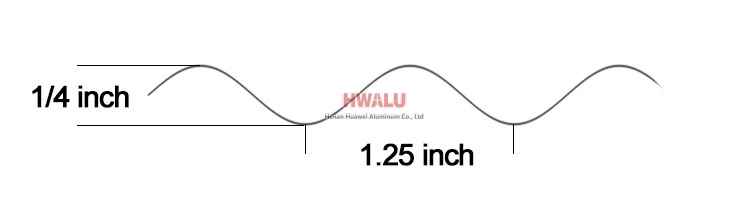

1 1/4 (1.25) inch by 1/4 inch、2 1/2 (2.5) inch by 1/2 inch、2.67 inches by 3/4 inch、2.67 inches by 7/8 inch、4.2 inches, etc.

Dimensions of corrugated aluminum roofing plate

Application

industrial and civil buildings use, warehouse ceilings, villa, special construction cover, large-span steel structure housing the roof tiles protection, house walls and interior and exterior decoration etc

Export countries and regions

Export all over the world: Nigeria ( Africa ), India ( Namakkal ), Ghana, etc

Aluminum sheet manufacturers near me

Henan Huawei Aluminum Co., Ltd. is the leader of many aluminum manufactures and suppliers in China. We strictly control the quality and focus on customers. We hope to have in-depth cooperation with you and provide you with high quality aluminum material products custom OEM services. If you want to get the newest and best prices by per kg ( kilogram ) or per ton standard weight, please contact us.

Aluminum sheet plate standard export packing

- The aluminum plate is paperclip or laminated to ensure that the surface of the aluminum plate is intact and free of scratches;

- Plastic film ( HDPE, PVC, PE or PET etc ) protection or hard kraft paper wrapping is used to prevent moisture and rain to ensure that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China, where there is more rain);

- Installed with wooden brackets and reinforced with steel straps to avoid collision during transportation and to ensure the geometry of the aluminum plate remains unchanged;

- For export products, we use wooden boxes and pallets with fumigation mark for packaging;

- We can also pack according to other packaging requirements of customers;