What is 5052 aluminum sheet/plate?

5052 alloy metal aluminum sheet plate belongs to 5000 series aluminum sheet, which is highly resistant to corrosion. It belongs It is an alloy that contains 0.25 percent chromium and 2.5 percent magnesium, and it belongs to 5 series. It’s widely used because of its formability and durability. It has high fatigue and medium static strength. It can be used in marine environments without the worry of corrosion.

This metal also has excellent thermal conductivity and low density, which is commonly found with other aluminum alloys. Its fatigue properties and endurance limit are excellent. The endurance limit is 125 MPa in an H34 temper and 115 MPa in an H32 temper.

5052 aluminum alloy in addition to a small amount of manganese solid solution, most of the formation of MnAl6. 5052 aluminum plate in the role of chromium and manganese similar to improve stress corrosion cracking ability, improve the base metal and weld strength, reduce the tendency of welding cracks, but its content generally does not exceed 0.35%.

Aluminium alloy 5052 in H32 temper has very good corrosion resistance to seawater and marine and industrial atmosphere. It also has very good weldability and good cold formability. It is a medium to high strength alloy with a strength slightly higher than 5251 and a medium to high fatigue strength.

5052 aluminum flat sheet is alloyed with 2.5% magnesium. The tensile strength range is 31 to 44 KSI. 5052 has excellent workability, weldability and corrosion resisitance.5052 Aluminum sheet Used for aircraft fuel tanks, storm shutters, refrigerator liners and panels.

5052 aluminum sheet

Parameters of 5052 alloy metal aluminum sheet plate

Equivalent name: a5052, 5052a, aa5052, 5052aa, al5052, 5052 aa, aa 5052, jis a5052p, al5052 class, aw5052 grade etc

Rolling method: Hot rolled ( digital casting, DC ), cold rolled, continuous casting rolling ( CC )

Temper

Soft HO, H11, H12, H13, H14, H15, H16, H17, H18, H19, H20, H21, H22, H23, H24, H25, H26, H27, H28, H29, H30, H31, H32, H33, H34, H35, H36, H37, H38, H39, H46, H111, H112, H114, H116, H131, H321 etc

Size: 4′ x 8′, 40×80, 12×12, 8ft by 20ft, 2000×6000 etc

Thickness

Unit ( mm ): ( thin ) 0.8, 1.2mm, 1.6mm, 2mm, 3mm, 4mm, 4.5mm, 5mm, 6mm, 7mm, 10mm, 16mm, 20mm ( thick ) etc

Unit ( inch ): .063, .125, .1875, 1/16″, 1/8”, 1″ etc

Surface Treatment: brushed, mirror finish, embossed pattern etc

Chemical composition of 5052 aluminum sheet

| Alloy |

Si |

Cu |

Mg |

Zn |

Mn |

Cr |

Fe |

Ti |

Others total |

Al |

| 5052 |

≤ 0.25 |

≤ 0.05 |

≤ 0.03 |

≤ 0.05 |

≤ 0.03 |

/ |

≤ 0.35 |

≤ 0.03 |

≤ 0.15 |

remainder |

Alloy 5052-H32 has a range of useful properties:

Decorative Finish/Hard Wearing/Non-Slip/Corrosion Resistant/Low Maintenance/Anti-Static/Light-weight.

5052 aluminium plate of Huawei is certificated to ASTM B209 and it can be cut to size at the customer’s need. The main content is Mg, which improves the strength of 5052 aluminium plate. Products with different thicknesses have different tensile and yield strengths, as well as elongation, all of which live to international standards. 5052 aluminium plate is stronger than 1100 and 3003 and it is an excellent candidate for most processing techniques.

Features of 5052 alloy aluminum sheet

- 5252 aluminum sheet has good oxidation and coloring effect and has better metal texture and metal hardness.

- 5252 aluminum sheet is Al-Mg series rust-proof aluminum alloy, which cannot be strengthened by heat treatment.

- The chemical composition of 5252 alloys is similar to that of 5A02 alloy, and its properties are basically the same as 5A02. The alloy has higher plasticity and lower strength.

- Although the 5052 aluminum sheet has medium strength, it has excellent corrosion resistance and is easy to manufacture.

Mechanical properties of 5052 aluminum sheet

| Alloy Temper |

Specified thickness |

Tensile

strength |

Yield

strength |

Elongation |

| (MPa) |

(MPa) |

(%) |

| 5052 HO/H111 |

0.3~0.63mm |

173-213 |

min66 |

min 15 |

| 0.63~1.2mm |

min 17 |

| 1.2~6.3mm |

min 19 |

| 6.3~50mm |

min 18 |

| 5052 h32 aluminum sheet or 5052 H22 |

0.4~0.63mm |

214-262 |

min159 |

min 4 |

| 0.63~1.2mm |

min 5 |

| 1.2~6.3mm |

min 7 |

| 6.3~50mm |

min 11 |

| 5052 h34 aluminum sheet or 5052 H24 |

0.4~0.63mm |

235-282 |

min180 |

min 3 |

| 0.63~1.2mm |

min 4 |

| 1.2~6.3mm |

min 6 |

| 6.3~50mm |

min 10 |

| aluminum sheet 5052 h36 or 5052 H26 |

0.1~0.32mm |

256-303 |

min200 |

min 2 |

| 0.32~0.63mm |

min 3 |

| 0.63~4mm |

min 4 |

| 5052/H38 or 5052 H28 |

0.15~0.32mm |

min269 |

min221 |

min 2 |

| 0.32~0.63mm |

min 3 |

| 0.63~3.2mm |

min 4 |

- Tensile strength σb (MPa): 173~244

- Conditional yield strength σ0.2 (MPa): ≥70

- Density: 2.68g/cm3

5052-H32 Aluminum has a tensile strength range of 31-44 KSI, and conforms to AMS QQ-A-250/8 and ASTM B209

5052-H32 Aluminum. When magnesium is used as the major alloying element, or in combination with manganese, the result is a moderate to high strength non-heat-treatable aluminum alloy.

Applications of 5052 aluminum sheets

5052 aluminum sheet is used for chemical and petrochemical equipment and components.

Treadplate, Boilermaking, Containers, Nameplates, Road Signs, Architectural Paneling, Welded Tubes, Chemical Industry, Irrigation, Desalination units, Pressure Vessels, Rivets, Construction, decoration, boat, building exterior decoration, bus body, road traffic sign, aircraft fuel tanks, storm shutters, refrigerator liners and panels, beer mold, laptop ( PC computer ) aluminium enclosure, precision parts, etc

5052 Aluminum sheet is widely used in products of strength requirement is not high. Products are often used in signs, billboards, building exterior decoration, bus body, tall buildings and factory wall body adornment, kitchen sink, lamp holder, fan blade, electronic parts, chemical equipment, mechanical parts, deep drawing of sheet or spinning concave ware, welding part, heat exchanger, clock surface and plate, plate, kitchenware, ornaments, reflective equipment, etc.

Marine grade 5052 aluminum sheet

5052 aluminium plate is used for marine applications due to its high resistance to saltwater corrosion and overall strength as compared to 3003 aluminium plate. It is easy to form, stamp, weld and finish.

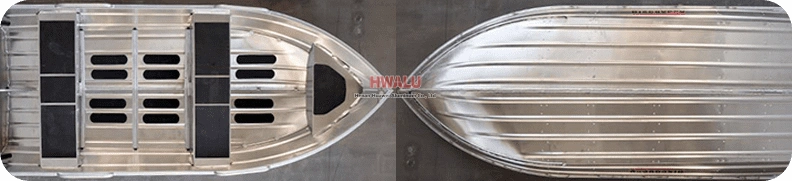

Marine grade 5052 aluminum sheet

Marine-grade 5052 aluminum sheet plate for boat building

- 5052 aluminium sheet is a commonly used Marine aluminum plate. The 5052 aluminum alloy belongs to the al-mg series alloy, which has a wide range of applications, excellent weldability, good corrosion resistance and cold working performance, moderate strength and good forming and processing performance.Fatigue resistance. Due to its excellent weldability and corrosion resistance, it is very suitable for Marine environment and is an ideal material for shipbuilding.

- 5052 marine grade alu alloy sheet is the preferred material for high-speed ships, such as fast ferries, yachts and offshore vessels. It is widely used in the manufacture of ship sheet metal parts, bottom plates, portholes, bottom plate and side plate

- The 5052 Marine grade al sheet produced by our company has no spalling, bubbles, rough surface and local mechanical damage. There are no cracks, rust spots and trace nitrate on the surface of aluminum plate. Is there. There are strict standards and standard quality inspection standards.

Anodized 5052 aluminum sheet plate for decorative parts

5252 aluminum sheets are used in the manufacture of decorative parts with higher strength, such as decorative parts for automobiles. After anodizing, it has a bright and transparent oxide film, so it is also widely used in mobile phone cases, air-conditioning cases, and other fields that require high oxidation effects and metal texture.

- 5052 high precision flat aluminum cast plates for aircraft

- 5052 ultra-wide aluminum sheets for the roof ( roofing sheet )

- 5052 h34 aluminum sheet for road traffic sign

- 5052 aluminum sheeting for beer mold

- 5052 corrugated aluminum sheet

Aluminum sheet manufacturers near me

Henan Huawei Aluminum Co., Ltd. is the leader of many aluminum manufactures and suppliers in China. We strictly control the quality and focus on customers. We hope to have in-depth cooperation with you and provide you with high quality aluminum material products custom OEM services. If you want to get the newest and best prices by per kg ( kilogram ) or per ton standard weight, please contact us.

Aluminum sheet plate standard export packing

- The aluminum plate is paperclip or laminated to ensure that the surface of the aluminum plate is intact and free of scratches;

- Plastic film ( HDPE, PVC, PE or PET etc ) protection or hard kraft paper wrapping is used to prevent moisture and rain to ensure that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in East China and South China, where there is more rain);

- Installed with wooden brackets and reinforced with steel straps to avoid collision during transportation and to ensure the geometry of the aluminum plate remains unchanged;

- For export products, we use wooden boxes and pallets with fumigation mark for packaging;

- We can also pack according to other packaging requirements of customers;